Ship Air Compressor – Marine Solution Guide 2025

Content Navigation

Marine Insight: Ship Air Compressor

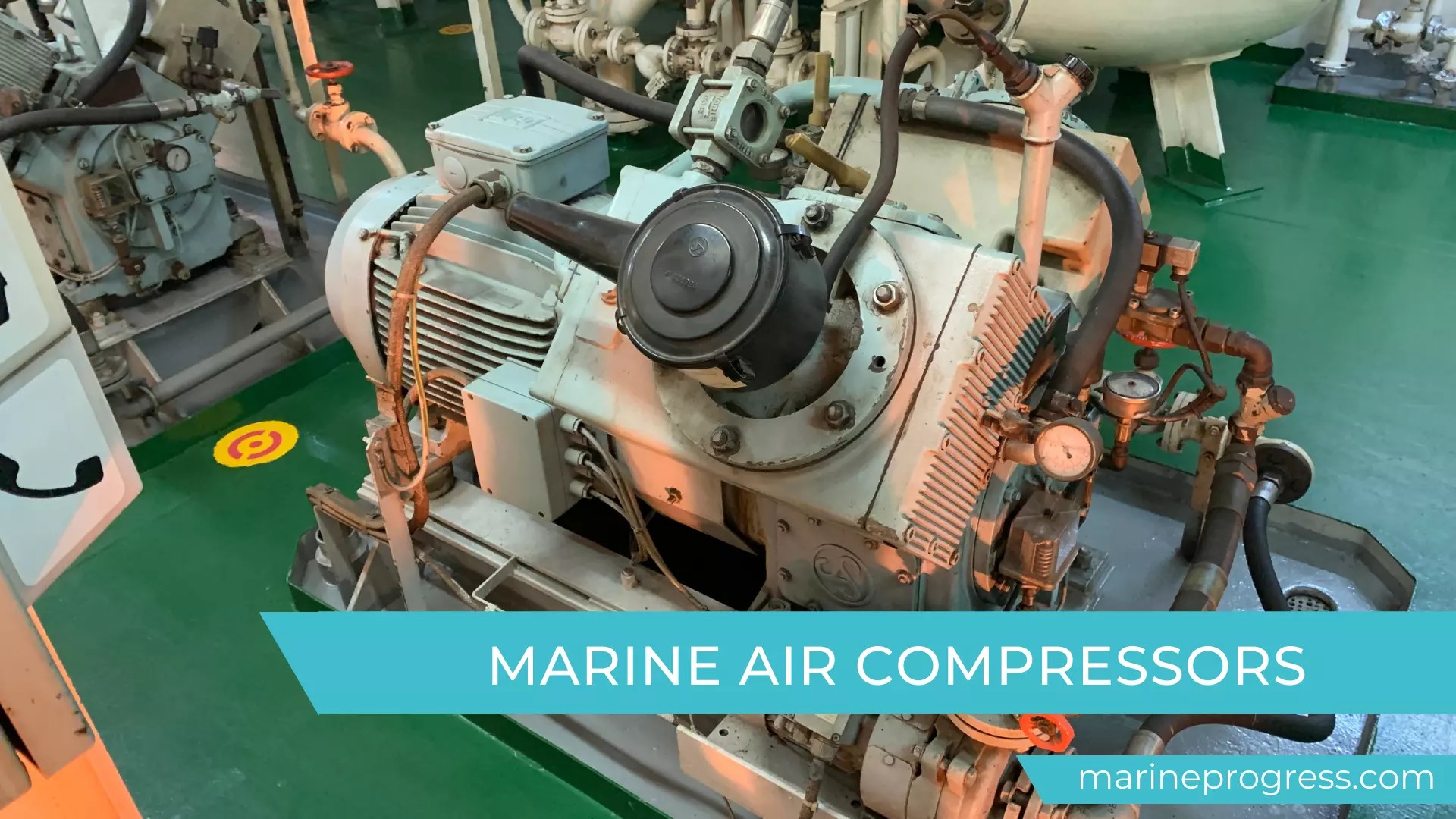

Marine air compressors are critical components in the operational safety and efficiency of commercial and naval vessels. These systems provide compressed air for a wide range of essential functions, including engine starting, pneumatic control systems, automation, and emergency services. Without a reliable air supply, a vessel’s main propulsion system may fail to start, leading to loss of maneuverability and potential safety hazards. In emergency scenarios such as blackout recovery or fire suppression, compressed air ensures rapid restart of auxiliary and main engines, enabling critical response actions. Additionally, compressed air powers safety systems such as whistle signals, hatch covers, and pneumatic valves, reinforcing the vessel’s overall safety infrastructure.

The demand for high-performance marine air compressors has increased with the expansion of global shipping fleets, stricter international maritime regulations, and the growing complexity of onboard automation systems. Classification societies such as ABS, DNV, LR, and CCS mandate strict compliance with performance and safety standards for air compressor systems, particularly regarding pressure stability, reliability, and resistance to harsh marine environments. As a result, vessel operators prioritize compressors that offer long service life, low maintenance requirements, and consistent output under variable load and climatic conditions.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted manufacturer of marine air compressors, delivering equipment that meets international standards and classification society requirements. Our compressors are engineered for durability, corrosion resistance, and optimal performance in saltwater and high-humidity environments. By integrating advanced cooling systems, high-efficiency motors, and robust filtration, Star Marine compressors ensure uninterrupted operation across diverse vessel types, including container ships, tankers, offshore support vessels, and fishing boats.

Sourcing marine air compressors from Star Marine China offers significant cost advantages without compromising quality. Our vertically integrated manufacturing process, strategic supply chain management, and in-house R&D capabilities allow us to deliver high-value solutions at competitive price points. Unlike OEMs based in Western markets, we provide equivalent or superior technical specifications at a lower total cost of ownership, including reduced lead times and responsive after-sales support. This cost efficiency is particularly beneficial for shipowners, shipbuilders, and marine equipment distributors seeking reliable, certified equipment within constrained budgets.

The following table outlines key performance specifications of Star Marine’s standard marine air compressor models:

| Model | Capacity (m³/min) | Working Pressure (bar) | Power (kW) | Classification Approval | Cooling Method |

|---|---|---|---|---|---|

| SMAC-10 | 1.0 | 30 | 7.5 | CCS, DNV, LR | Air-Cooled |

| SMAC-25 | 2.5 | 30 | 18.5 | ABS, DNV, LR, BV | Water-Cooled |

| SMAC-50 | 5.0 | 30 | 37 | ABS, DNV, LR, CCS, BV | Water-Cooled |

| SMAC-75 | 7.5 | 30 | 55 | ABS, DNV, LR, CCS, BV | Water-Cooled |

By combining technical excellence with cost-effective manufacturing, Hangzhou Star Marine Technology provides marine operators with a strategic advantage in maintaining safety, compliance, and operational continuity.

Technical Specs & Approval

Technical Specifications: Marine Air Compressors

Hangzhou Star Marine Technology Co. Ltd. designs and manufactures marine air compressors engineered to meet the rigorous demands of global shipping operations. Our compressors adhere to ISO 8528 (reciprocating) and ISO 1217 (rotary) standards, with full compliance to SOLAS Chapter II-1 regulations and classification society requirements (DNV, ABS, LR, CCS). Critical parameters are optimized for reliability in saltwater environments, ensuring uninterrupted vessel operations across all sea conditions. Below is a summary of core technical specifications for our standard marine air compressor series.

| Parameter | Standard Range | Typical Configuration | Application Notes |

|---|---|---|---|

| Discharge Pressure | 7 MPa to 30 MPa | 30 MPa max for HP systems | 30 MPa units certified for main engine starting air; 7–10 MPa for auxiliary service |

| Flow Rate (FAD) | 0.5 m³/min to 50 m³/min | Customizable staging | Matched to vessel air demand profiles; dual-compressor setups for redundancy |

| Cooling Method | Sea Water or Air | Jacketed sea water cooling standard | Corrosion-resistant titanium/brass heat exchangers; air-cooled variants for enclosed spaces |

| Drive Type | Electric or Diesel | 440V/60Hz marine-grade motor | ATEX-certified options for hazardous zones; diesel backup for emergency systems |

| Lubrication | Oil-Lubricated or Oil-Free | ISO 6743-3A synthetic marine oil | Oil-free compressors for instrument air per ISO 8573-1 Class 0 |

| Materials | Cast Iron/Stainless Steel | SS316L cylinder liners, duplex valves | All wetted parts resistant to seawater corrosion; non-sparking components per ADR |

| Control System | PLC with HMI | Auto-start/stop, pressure sequencing | Integrated with ship’s automation; remote monitoring via NMEA 2000 |

| Noise Level | ≤78 dB(A) at 1m | Vibration-damped mounting | Compliant with IMO MSC/Circ.152 guidelines for machinery spaces |

Discharge pressure capabilities define the compressor’s operational role. Units rated to 30 MPa serve critical high-pressure functions such as main propulsion engine starting systems, where instantaneous air delivery at 25–30 MPa is mandatory under SOLAS II-1/26. Lower-pressure variants (7–10 MPa) support deck machinery, pneumatic controls, and general service air networks. All high-pressure models undergo 1.5x working pressure hydrostatic testing per PED 2014/68/EU Category IV.

Flow rate selection directly impacts vessel operational efficiency. Our engineering team conducts air demand audits to size compressors precisely, avoiding energy waste from oversized units while ensuring reserve capacity during peak loads. Rotary screw compressors dominate flow ranges above 10 m³/min for continuous duty cycles, whereas reciprocating models excel in intermittent high-pressure applications below 5 m³/min.

Cooling methodology is pivotal for thermal management in tropical or high-ambient conditions. Sea water cooling remains the maritime industry standard due to superior heat dissipation, but requires robust material selection to prevent biofouling and galvanic corrosion. Hangzhou Star’s titanium tube coolers withstand 30+ years of seawater exposure, validated through 5,000-hour accelerated corrosion testing. Air-cooled alternatives feature oversized radiators with marine-grade epoxy coatings for engine room installations where seawater intake is impractical.

All compressors undergo factory acceptance testing per ISO 1217 Annex C, including 72-hour endurance runs at 110% load. Documentation packages include EU Declaration of Conformity, classification society certificates, and maintenance protocols aligned with IACS Rec. 173. This technical foundation ensures seamless integration into newbuilds and retrofits while meeting global export compliance frameworks.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive marine air compressor solutions tailored for both new shipbuilding projects and vessel repair operations. As a trusted partner in the maritime industry, we specialize in providing reliable, high-performance air compression systems that meet international marine standards, including ISO 8573, SOLAS, and classification society requirements such as CCS, ABS, DNV, LR, and BV. Our integrated approach ensures seamless integration of air compressors into vessel systems, supporting critical functions such as main engine starting, pneumatic control, deck machinery operation, and service air supply.

For new shipbuilding projects, Star Marine collaborates closely with shipyards and design engineers from the early stages of vessel development. Our engineering team provides technical consultancy to select the optimal compressor configuration based on vessel type, operational profile, and engine requirements. We offer both oil-lubricated and oil-free reciprocating and screw-type compressors, with capacities ranging from 0.5 m³/min to over 20 m³/min, ensuring compatibility with a wide range of marine applications. Our systems are designed for durability in harsh marine environments, featuring corrosion-resistant materials, compact footprints, and low-noise operation.

In ship repair and retrofit scenarios, Star Marine provides rapid-response service and replacement solutions to minimize downtime. Our global spare parts network and modular design philosophy allow for quick field repairs and system upgrades. We support legacy compressor models across major brands, offering direct replacements or modernized upgrades with improved energy efficiency and digital monitoring capabilities. Our technical service team is available 24/7 to assist with troubleshooting, commissioning, and on-site support, ensuring fast turnaround during dry dock periods.

All Star Marine compressors undergo rigorous factory testing, including performance validation, pressure testing, and vibration analysis, to guarantee reliability before shipment. We provide full documentation packages, including P&ID diagrams, operation manuals, and classification certificates, to streamline approval processes with船级社 and regulatory bodies.

The following table outlines key product specifications and service capabilities:

| Parameter | Specification Range |

|---|---|

| Flow Rate | 0.5 – 20 m³/min |

| Working Pressure | 30 – 35 bar |

| Drive Type | Electric or Diesel Engine Driven |

| Cooling Method | Air or Water Cooled |

| Lubrication | Oil-Lubricated or Oil-Free |

| Compliance | ISO 8573, SOLAS, CCS, ABS, DNV, LR, BV |

| Control System | Manual, Automatic, or PLC with Remote Monitoring |

| Service Response Time | < 48 hours for global technical support |

With a commitment to engineering excellence and customer-centric service, Hangzhou Star Marine Technology ensures that every air compressor system we deliver enhances vessel safety, operational efficiency, and uptime—whether in new construction or repair scenarios.

Packaging & Logistics

Packaging & Logistics for Marine Air Compressors

Proper packaging and logistics execution are non-negotiable elements in the successful global export of marine air compressors. These critical propulsion and auxiliary system components demand robust protection against the severe environmental stresses encountered during maritime transit, including salt spray, extreme humidity, vibration, and handling impacts. At Hangzhou Star Marine Technology, we implement stringent, industry-standard packaging protocols specifically engineered for the marine environment to ensure your compressor arrives at the vessel or shipyard in flawless operational condition, safeguarding your investment and project timelines.

Our primary packaging solution for marine air compressors utilizes custom-engineered wooden export crates constructed from kiln-dried, certified lumber. These crates strictly adhere to the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This globally recognized regulation mandates heat treatment of all raw wood packaging material to eliminate pests and prevent cross-border biological contamination. Each wooden component bears the official, legible ISPM 15 mark, signifying compliance with the required thermal process (minimum 56°C core temperature for 30 minutes) and eliminating the need for chemical fumigation. This certification is essential for smooth customs clearance in virtually all destination countries. The crates are internally lined with VCI (Vapor Corrosion Inhibitor) paper to actively combat rust formation on all metal surfaces throughout the voyage. Critical internal components are further secured using custom-cut polyethylene foam inserts and vibration-dampening mounts to prevent movement and shock damage.

The following table details the standard specifications for our ISPM 15 compliant wooden export crates:

| Feature | Specification Detail | Compliance Standard |

|---|---|---|

| Material | Kiln-dried Softwood (Pine/Spruce) | ISPM 15 |

| Treatment | Mandatory Heat Treatment (HT) | ISPM 15 |

| Marking | Legible ISPM 15 Stamp (HT, Country Code, Producer ID) | ISPM 15 |

| Interior Lining | Multi-layer VCI Corrosion Inhibitor Paper | ASTM D6039 |

| Internal Support | Custom Polyethylene Foam Inserts & Vibration Mounts | ISO 11600 |

| Exterior Finish | Waterproof Coating (Optional Heavy-Duty Sealant) | ISO 2813 |

For larger compressor units or specific customer requirements regarding handling efficiency, we utilize heavy-duty, galvanized steel pallets as a foundational element. These pallets provide exceptional structural integrity and are inherently resistant to moisture and corrosion, crucial for marine environments. Units are securely fastened to the pallet using high-tensile steel strapping and corner protectors, then fully enclosed within a weatherproof polyethylene shrink wrap or fitted wooden crate as described above. This hybrid approach ensures optimal stability during containerization and terminal handling.

All Hangzhou Star Marine Technology exports originate from China’s premier deep-water ports: Ningbo-Zhoushan Port and Shanghai Port. Both facilities offer world-class infrastructure, extensive global shipping line connectivity, and streamlined customs procedures essential for time-sensitive marine equipment shipments. Our dedicated export logistics team manages every step, from inland trucking coordination and port documentation (including accurate commercial invoices, packing lists, and certificates of origin) to final container stuffing under supervision. We ensure seamless integration with your nominated freight forwarder or provide comprehensive door-to-port logistics solutions, guaranteeing adherence to shipping schedules and full regulatory compliance for air compressors destined for any global shipyard or vessel. This meticulous attention to packaging and port execution forms the bedrock of reliable, damage-free delivery.

Contact Star Marine

For marine operators, shipbuilders, and equipment suppliers seeking reliable and high-performance air compression solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted manufacturer and exporter of marine air compressors. Our engineered systems are designed to meet the rigorous demands of maritime environments, ensuring consistent performance, durability, and compliance with international marine standards including ISO, CCS, and other classification society requirements. As a specialized provider in the marine equipment sector, we understand that selecting the right air compressor involves technical precision, operational compatibility, and long-term service support.

If you are currently sourcing marine air compressors for vessel installation, retrofit projects, or fleet maintenance, we invite you to connect directly with our Product Manager, Kacher YE. With extensive experience in marine system integration and export logistics, Kacher serves as the primary technical liaison for global clients, offering expert guidance from initial specification review through to after-sales support. Whether your requirement involves low-pressure starting air systems, medium-pressure control air units, or complete compressor packages with dryers and receivers, Kacher can assist in selecting the optimal configuration tailored to your vessel type, engine requirements, and operational profile.

We encourage direct communication to discuss technical specifications, customization options, certification needs, and shipping terms. Our team supports inquiries in both English and Chinese and is equipped to provide detailed product documentation, 3D models, performance curves, and factory test reports upon request. Hangzhou Star Marine Technology maintains a streamlined export process, ensuring compliance with INCOTERMS 2020, accurate customs classification, and timely shipment via containerized or break-bulk methods depending on unit size and destination.

To initiate a technical discussion or request a formal quotation, please contact Kacher YE at [email protected]. We respond to all inquiries within 12 business hours and can schedule virtual meetings or factory video tours for high-priority projects. For urgent matters, direct messaging via professional platforms such as LinkedIn is also available upon connection request.

Below is an overview of our standard marine air compressor series for reference:

| Model Series | Air Output (m³/min) | Max Pressure (bar) | Power Supply (V/Hz) | Cooling Method | Classification Approval |

|---|---|---|---|---|---|

| SMAC-LP10 | 1.0 | 30 | 380/440V, 50/60Hz | Water-cooled | CCS, ISO 8573 |

| SMAC-MP15 | 1.5 | 70 | 440V, 60Hz | Air-cooled | CCS, DNV-GL (upon request) |

| SMAC-HP20 | 2.0 | 250 | 380V, 50Hz | Water-cooled | CCS, ABS, LR |

| SMAC-CP30 | 3.0 | 30 | 440V, 60Hz | Air-cooled | CCS, RINA, NK |

All units are manufactured under ISO 9001-certified processes and undergo 100% factory acceptance testing. Partner with Hangzhou Star Marine Technology for technically sound, export-ready marine air compressors backed by responsive engineering support. Reach out today to optimize your vessel’s compressed air systems with a trusted industry provider.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160