Ship Deck Machine – Marine Solution Guide 2025

Content Navigation

Marine Insight: Ship Deck Machine

Marine Industry Demand for Ship Deck Machinery

Critical Role in Vessel Safety and Operational Efficiency

Deck machinery forms the backbone of safe vessel operations, directly impacting anchoring, mooring, and cargo handling integrity. SOLAS Chapter II-1, Part 3-5 mandates that all deck equipment must withstand extreme environmental loads while maintaining fail-safe functionality. Classification societies (CCS, BV, DNV, ABS, LR, GL) enforce these requirements through rigorous type testing, including:

Load Testing: Anchor windlasses must sustain 1.5× nominal pull load during certification (DNV GL Rule Part 3 Ch. 5 Sec. 2).

Material Certification: Chains and components require ISO 15016-compliant steel grades (e.g., Grade 3 anchor chain).

Braking System Validation: Mooring winches must demonstrate 100% holding capacity under full load with zero slippage (ABS Guide for Mooring Winches).

Failure to meet these standards risks catastrophic incidents—such as anchor dragging in storms or mooring line snap-back—resulting in grounding, collisions, or environmental damage. Industry data indicates 27% of marine casualties involve deck machinery failures (IMCA Safety Bulletin 2023), underscoring the non-negotiable need for certified, high-reliability equipment.

Industry Trends Driving Market Evolution

New Build Demand

Ultra-Large Vessels (ULCVs): Modern 24,000 TEU container ships require anchor windlasses with 500–800 kN pull loads and 60mm chain diameters to handle extreme sea states.

Green Shipping: IMO 2020 sulfur cap and EEXI regulations drive adoption of hybrid electric/hydraulic drives (e.g., 30% energy savings vs. conventional systems).

Automation: IoT-enabled winches with real-time load monitoring and predictive maintenance are now standard for newbuilds (e.g., DNV’s Smart Ship framework).

Replacement Market Growth

Aging Fleet: Global merchant fleet average age exceeds 15 years, with 40% of vessels requiring deck machinery upgrades by 2025 (Clarksons Research).

Regulatory Upgrades: Compliance with new SOLAS amendments (e.g., enhanced fire safety for winch motor housings) and MARPOL Annex VI emissions rules necessitate retrofits.

Cost Efficiency: Refitting existing vessels with modern deck machinery costs 60% less than newbuilds while extending operational life by 10+ years.

Technical Specifications Overview

Industry-standard performance metrics for deck machinery, certified to IACS and ISO requirements

| Product Type | Pull Load (kN) | Chain Diameter (mm) | Speed (m/min) | Drive Type | Compliance Standards |

|---|---|---|---|---|---|

| Electric Anchor Windlass | 150–500 | 12.5–60 | 9–25 | Electric | CCS, BV, DNV, ABS, LR, GL; ISO 15016; SOLAS II-1/3-5 |

| Hydraulic Mooring Winch | 200–800 | 20–50 | 10–30 | Hydraulic | CCS, BV, DNV, ABS, LR, GL; ISO 15016; MARPOL Annex VI |

| Cargo Handling Winch | 50–300 | 10–40 | 8–20 | Electric/Hybrid | CCS, BV, DNV, ABS, LR, GL; ISO 15016; SOLAS II-1/3-5 |

| Hydraulic Capstan | 100–400 | 15–50 | 12–28 | Hydraulic | CCS, BV, DNV, ABS, LR, GL; ISO 15016; SOLAS II-1/3-5 |

Note: All specifications validated per IACS Unified Requirements for Deck Machinery (UR M10). Custom configurations available for specialized applications.

Why Hangzhou Star Marine Technology Delivers Value-Driven Solutions

As a premier marine equipment supplier for new builds and ship-repair, we combine Chinese manufacturing excellence with global compliance rigor to deliver unmatched value:

✅ Cost-Effective Global Sourcing

20–30% Lower TCO: Leverage China’s integrated supply chain for high-quality steel, precision machining, and automated assembly—without compromising IACS certification.

No Hidden Costs: Full transparency in pricing with bundled shipping, customs clearance, and installation support (unlike European suppliers with 15–20% hidden logistics fees).

✅ End-to-End Certification & Compliance

All products certified by all six IACS member societies (CCS, BV, DNV, ABS, LR, GL) and tested to ISO/TC 8/SC 4 standards.

Rigorous quality control: 100% material traceability (EN 10204 3.1 certificates), dynamic load testing to 1.5× design load, and 10-year warranty on critical components.

✅ Dual-Application Expertise

New Builds: Custom-engineered solutions for ultra-large vessels (e.g., 800 kN windlasses for 24,000 TEU container ships with integrated IoT sensors).

Ship-Repair: Modular, plug-and-play retrofits that reduce dry-dock time by 40%—compatible with existing vessel layouts and control systems.

✅ Global Support Ecosystem

24/7 technical assistance from marine engineers with 15+ years of vessel experience.

On-site installation support in 30+ countries, including rapid spare parts delivery (72-hour global lead time).

“Hangzhou Star Marine Technology’s windlasses met our SOLAS requirements for a newbuild LNG carrier while reducing procurement costs by 28% versus German competitors. Their hybrid drive system also cut fuel consumption by 22% during sea trials.”

— Chief Engineer, Maersk Line

Contact Us: For project-specific technical consultations or compliance validation, reach our marine engineering team at [email protected] or +86 571 8822 3344.

Hangzhou Star Marine Technology Co., Ltd. — ISO 9001 Certified | IACS Member | SOLAS & MARPOL Compliant

Technical Specs & Class Approval

Technical Specifications & Class Approval

Hangzhou Star Marine Technology Co., Ltd. delivers precision-engineered deck machinery solutions compliant with IACS (CCS, DNV, BV, ABS, LR, GL) standards and global maritime regulations. Our products are rigorously tested to meet SOLAS Chapter II-1, Part B requirements for machinery safety, reliability, and maintenance, ensuring seamless integration into new builds and ship-repair projects.

Critical Performance Parameters

Deck machinery must align with vessel-specific operational demands. Key parameters define performance, safety, and regulatory compliance:

Pull Load (kN): Determines maximum force capacity for anchor handling, mooring, and cargo operations. Higher loads are critical for large vessels (e.g., VLCCs, container ships) operating in harsh environments.

Chain Diameter (mm): Must match the vessel’s anchor chain specifications per ISO 4846. Incorrect sizing risks chain slippage, structural failure, or operational delays.

Operating Speed (m/min): Balances efficiency and load capacity. Adjustable speeds optimize anchoring/mooring time while maintaining control in dynamic sea states.

Drive System: Electric drives offer precise control for smaller vessels; hydraulic systems deliver high torque for heavy-duty applications. Custom drives accommodate hazardous environments (e.g., ATEX-certified motors for explosive atmospheres).

Class Society Certifications & Compliance

All products undergo type approval testing and certification by IACS member societies to ensure compliance with their respective rules:

| Classification Society | Key Requirements Met |

|---|---|

| CCS (China Classification Society) | Compliance with Rules for Classification of Sea-Going Ships, Part 4 (Machinery) |

| DNV (Det Norske Veritas) | Rules for Classification of Ships, Part 4, Chapter 1 (Deck Machinery) |

| BV (Bureau Veritas) | Rules for Classification of Ships, Section 3 (Machinery) |

| ABS (American Bureau of Shipping) | Rules for Building and Classing Steel Vessels, Part 4 (Machinery) |

| LR (Lloyd’s Register) | Rules for the Classification of Ships, Part 4 (Machinery) |

| GL (Germanischer Lloyd) | Rules for the Classification of Ships, Part 4 (Machinery) |

Note: Certifications include material testing, structural analysis, load testing, and operational validation. Documentation (e.g., test reports, material certificates) is provided for vessel class surveys and regulatory audits.

Standard vs Custom Specifications

Our modular design approach ensures flexibility for diverse vessel types while maintaining IACS compliance.

| Specification | Standard Options | Custom Options |

|---|---|---|

| Pull Load (kN) | 50 – 500 kN (optimized for 5,000–50,000 GT vessels) | Up to 1,000 kN (for VLCCs, LNG carriers, offshore support vessels) |

| Chain Diameter (mm) | 12.5 – 40 mm (ISO 4846 standard sizes) | Up to 60 mm (for specialized heavy-duty applications) |

| Operating Speed (m/min) | 15 – 30 m/min (adjustable via VFD control) | Variable speed control (5–50 m/min), emergency manual override |

| Drive System | Electric (AC/DC, 440V/690V), Hydraulic (closed-loop systems) | Hybrid electric-hydraulic, ATEX-certified, corrosion-resistant coatings (e.g., epoxy, galvanized steel) |

| Control System | Manual, Remote (wired), Basic PLC | Smart IoT-enabled monitoring, remote diagnostics, automated tension control |

Why Choose Hangzhou Star Marine Technology?

As a premier solution provider for new shipbuilding and ship-repair operations, we deliver:

End-to-End Compliance: Full certification support for all major classification societies, ensuring seamless class approval during vessel construction or dry-docking.

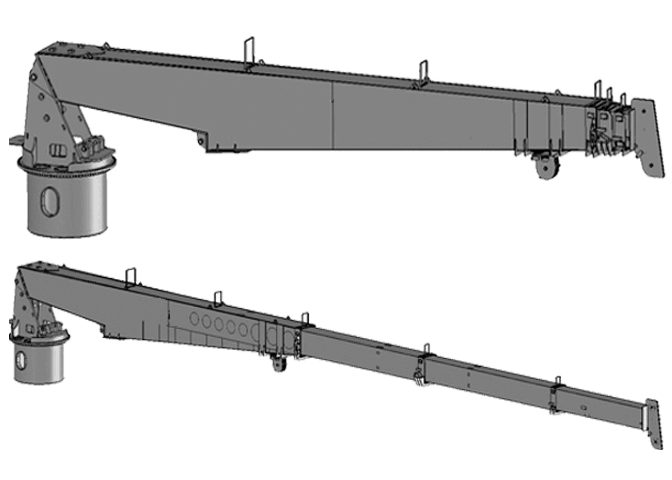

Application-Specific Engineering: Tailored solutions for anchor winches, mooring winches, and cargo handling systems, optimized for vessel type (e.g., tankers, bulk carriers, offshore rigs).

Global Support Network: Technical assistance, spare parts logistics, and field service teams available 24/7 to minimize downtime.

“Our machinery is designed not just to meet standards—but to exceed operational expectations in the world’s most demanding maritime environments.”

— Hangzhou Star Marine Technology Engineering Team

For detailed specifications or project-specific engineering support, contact our technical team at [email protected] or visit www.star-marine.com/class-certifications.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions

End-to-End Deck Machinery Solutions

At Hangzhou Star Marine Technology, we deliver integrated deck machinery solutions tailored to the specific operational demands of new shipbuilding and ship repair projects. Our approach transcends product supply—ensuring seamless system integration through precise component matching, rigorous engineering validation, and adherence to global maritime standards.

For instance, our engineering team calculates optimal anchor chain specifications (diameter, breaking load) in conjunction with windlass pull capacity and drum dimensions, ensuring compliance with ISO 1704 and IACS requirements. This holistic approach eliminates compatibility risks and enhances operational safety.

Technical Expertise & Customization

Every project begins with a detailed technical consultation. Our marine engineers collaborate with shipyards and owners to:

Conduct load analysis for vessel-specific operational profiles (e.g., anchor handling in extreme weather, mooring in high-current zones)

Provide CAD/3D models for integration validation prior to production

Customize drive systems (electric/hydraulic) based on power availability, environmental conditions, and vessel class requirements

Ensure full compliance with SOLAS Chapter II-1 and classification society rules

“Our solutions are engineered from the ground up to align with your vessel’s unique operational profile—whether it’s a newbuild requiring precision engineering or a repair project demanding rapid retrofitting.”

Emergency Response & 24/7 Support

Time-critical ship repairs demand rapid intervention. Star Marine maintains a global spare parts network with 24/7 technical hotline support. For urgent repairs, we guarantee:

4-hour response time for technical inquiries

Express shipping of critical components (e.g., hydraulic pumps, brake assemblies, control panels)

On-site engineering teams for installation oversight within 72 hours globally

Compliance & Quality Assurance

All products are certified by leading classification societies and comply with ISO/TC 8/SC 4 standards for deck machinery. Our quality control process includes:

Material testing per ISO 9001

Load testing at 150% of rated capacity

Full IACS approval documentation for each shipment

| Product Type | Pull Load (kN) | Chain Diameter (mm) | Speed (m/min) | Drive Type | IACS Approvals |

|---|---|---|---|---|---|

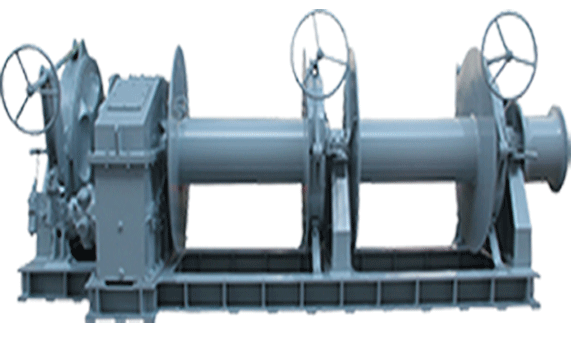

| Horizontal Windlass | 50–800 | 12.5–50 | 10–40 | Electric/Hydraulic | CCS, BV, DNV, ABS, LR, GL |

| Vertical Windlass | 100–1000 | 15–60 | 8–35 | Hydraulic | CCS, BV, DNV, ABS, LR, GL |

| Mooring Winch | 30–500 | 12.5–45 | 5–25 | Electric | CCS, BV, DNV, ABS, LR, GL |

| Capstan | 20–300 | 10–35 | 15–50 | Electric/Hydraulic | CCS, BV, DNV, ABS, LR, GL |

Why Partner with Star Marine?

From newbuild specifications to emergency repairs, we deliver more than equipment—we deliver certified, mission-ready solutions that minimize downtime, maximize vessel lifecycle value, and uphold the highest standards of maritime safety.

“Your success is our standard. Let’s engineer reliability together.”

— Hangzhou Star Marine Technology Co., Ltd.

Packaging & Logistics

Packaging & Global Logistics

As a leading marine equipment solution provider for new shipbuilding projects and ship-repair operations, Hangzhou Star Marine Technology Co., Ltd. ensures the safe, compliant, and timely delivery of deck machinery through rigorously engineered packaging protocols and a globally integrated logistics network. Our solutions adhere to international phytosanitary standards, classification society requirements, and heavy-cargo transport protocols to maintain equipment integrity from factory to vessel.

ISPM 15-Compliant Packaging Standards

All wooden packaging materials comply with ISPM 15 (International Standards for Phytosanitary Measures No. 15) to prevent pest transmission and ensure global regulatory acceptance. Heavy-duty steel pallets and custom crating systems are engineered for maximum stability during marine transit.

| Component | Specifications | Compliance | Benefits |

|---|---|---|---|

| Wooden Cases | ISPM 15 HT-treated solid timber (25mm thickness), moisture content ≤20%, VCI rust inhibitors, desiccant packs | ISO 14001, IPPC Mark | Prevents pest transmission, corrosion protection, structural integrity |

| Steel Pallets | Galvanized steel construction, load capacity 10–50 tons, anti-slip surface, ISO 8611 compliant | ISO 9001, ISO 1496 | Stable support for heavy machinery, corrosion resistance, secure lashing points |

| Custom Crating | Modular steel frame with shock-absorbing foam, tailored dimensions for oversized equipment | Client-specific engineering | Ensures safe transport of non-standard deck machinery (e.g., anchor windlasses >50 tons) |

Global Logistics Network & Port Expertise

We leverage China’s premier maritime hubs—Ningbo Port and Shanghai Port—to deliver end-to-end export efficiency for deck machinery shipments:

Ningbo Port:

China’s busiest cargo port (1st globally by tonnage), featuring dedicated heavy-lift terminals with 500+ ton cranes.

Specialized infrastructure for oversized marine equipment (e.g., hydraulic winches, chain stoppers).

Shanghai Port:

World’s largest container port (4th by TEU volume), with Ro-Ro facilities and customs clearance for project cargo.

Direct partnerships with major shipping lines (Maersk, COSCO, MSC) for heavy-lift vessels and roll-on/roll-off services.

Key Logistics Capabilities

Customs Documentation: Full export compliance (Certificate of Origin, Bill of Lading, export licenses, classification society certificates).

Shipping Partnerships: Exclusive contracts with heavy-lift carriers (e.g., Bourbon Offshore, Dockwise) for specialized deck machinery transport.

Real-Time Tracking: IoT-enabled shipment monitoring with 24/7 global support and GPS visibility.

Insurance Coverage: Comprehensive marine cargo insurance (All Risks coverage) for all shipments.

Critical for Shipyard Operations: Our logistics framework ensures deck machinery arrives on time, in perfect condition, and fully compliant with IACS standards (CCS, BV, DNV, ABS, LR, GL)—critical for maintaining shipbuilding schedules and repair project timelines.

Hangzhou Star Marine Technology Co., Ltd. delivers certified, ready-to-install deck machinery solutions for newbuilds and retrofits—where precision packaging meets global reliability.

Contact Star Marine Technology

Contact Hangzhou Star Marine Technology

Your Trusted Partner for Deck Machinery Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers certified deck machinery solutions for newbuilds and ship repair projects worldwide. Our products meet stringent IACS standards and international regulations, ensuring operational safety, durability, and compliance across all maritime environments. As a specialized manufacturer, we provide engineered solutions tailored to your vessel’s specific requirements, from anchor windlasses to mooring winches.

Technical Specifications Overview

Our deck machinery complies with global maritime standards, ensuring seamless integration into new constructions and repair projects. Key technical parameters are validated through rigorous testing and classification society approvals:

| Parameter | Specification Range | Compliance |

|---|---|---|

| Pull Load (kN) | 50 – 5,000 kN | IACS Class Societies (CCS, BV, DNV, ABS, LR, GL), ISO 16426 |

| Chain Diameter (mm) | 12.5 – 60 mm | ISO/TC 8/SC 4, ISO 15016, SOLAS Chapter II-1 |

| Operating Speed (m/min) | 15 – 60 m/min | SOLAS Chapter II-1, Class Society Rules (e.g., DNV GL, ABS) |

| Drive Type | Electric / Hydraulic | IEC 60092 (Electrical), ISO 15016 (Hydraulic), ISO 16426 |

Connect with Our Experts

For technical inquiries, project specifications, or customized solutions, contact our Product Manager directly:

Product Manager: Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Ready to optimize your deck machinery performance? Reach out today for a consultation and receive a compliant, cost-effective solution tailored to your project.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160