Ship Deck Machine – Marine Solution Guide 2025

Content Navigation

Marine Insight: Ship Deck Machine

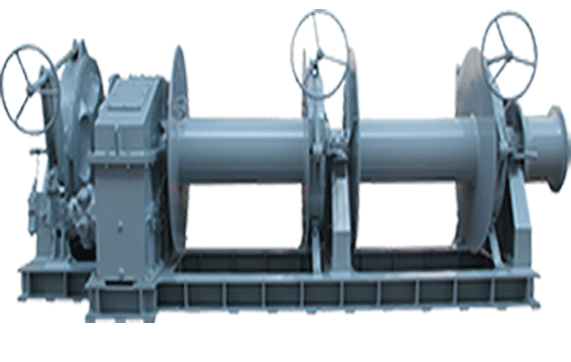

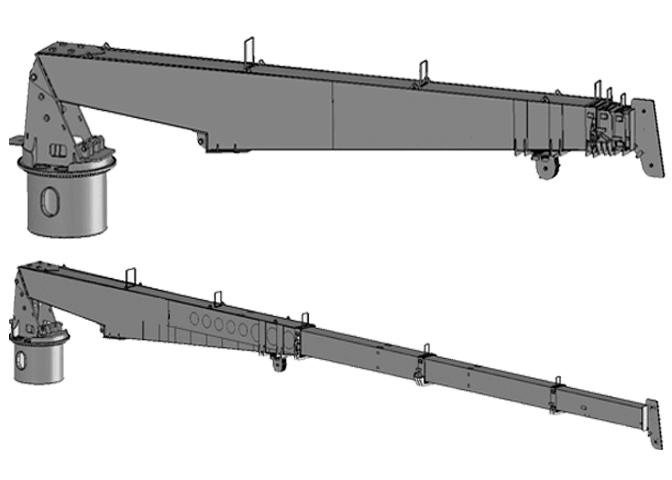

Marine deck machinery plays a critical role in ensuring the safe and efficient operation of vessels across all maritime sectors. Ship deck machines, including mooring winches, anchor windlasses, deck cranes, and hatch cover systems, are essential for vessel maneuvering, cargo handling, and overall safety at sea. These systems are engineered to withstand harsh marine environments, including saltwater exposure, extreme weather, and continuous mechanical stress. Their reliable performance directly impacts crew safety, operational efficiency, and compliance with international maritime regulations such as SOLAS (Safety of Life at Sea) and classification society standards.

The importance of high-quality deck machinery cannot be overstated. During berthing and unberthing operations, mooring winches must provide precise tension control to secure the vessel safely alongside a quay. Anchor windlasses are responsible for deploying and retrieving anchors under heavy loads, often in emergency situations where failure could lead to drifting and potential collision. Similarly, deck cranes and lifting appliances must operate with accuracy and fail-safe mechanisms to prevent cargo loss or injury. Any malfunction in these systems can compromise vessel integrity and endanger lives, making the selection of robust, well-engineered equipment a top priority for shipowners and operators.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted manufacturer and exporter of marine deck machinery, serving clients across Asia, Europe, Africa, and the Americas. Our products are designed in accordance with international standards and undergo rigorous quality control processes, including material certification, non-destructive testing, and functional performance validation. By integrating advanced hydraulic, electric, and electro-hydraulic drive systems, our deck machines deliver consistent performance under demanding conditions.

Sourcing deck machinery from Star Marine China offers significant cost advantages without compromising quality. Our vertical integration model allows us to control production from raw material sourcing to final assembly, reducing overhead and lead times. Additionally, our strategic location in Hangzhou provides access to efficient logistics networks, enabling competitive freight rates and faster delivery schedules. The Chinese manufacturing ecosystem supports economies of scale, which translates into cost savings passed directly to the client.

The following table outlines key product categories and comparative advantages offered by Hangzhou Star Marine Technology:

| Product Category | Load Capacity Range | Drive Type Options | Compliance Standards | Average Lead Time (weeks) |

|---|---|---|---|---|

| Mooring Winches | 50 kN – 1,200 kN | Hydraulic, Electric | ISO 5860, IACS M22 | 10–14 |

| Anchor Windlasses | 50 kN – 800 kN | Electro-Hydraulic, Electric | ISO 3912, ABS, DNV | 8–12 |

| Deck Cranes | 1T – 50T SWL | Hydraulic, Electrical | ISO 10278, EN 13852 | 12–16 |

| Hatch Cover Systems | Custom (up to 36m span) | Hydraulic, Mechanical | SOLAS II-1/3-7, IACS UR S11 | 16–20 |

By combining engineering excellence with cost-effective manufacturing, Hangzhou Star Marine Technology ensures that ship operators receive reliable, certified deck machinery that enhances safety and operational performance. Our commitment to quality and customer support makes us a preferred partner in the global marine supply chain.

Technical Specs & Approval

Technical Specifications for Ship Deck Machinery Systems

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures ship deck machinery systems to stringent international maritime standards, ensuring optimal performance, safety, and durability across global operational environments. Our deck machinery portfolio, including windlasses, mooring winches, and capstans, is engineered for reliability in demanding sea conditions. Key technical parameters are rigorously validated through ISO 9001-certified processes and third-party classification society approvals. All units undergo salt spray testing per ASTM B117 and dynamic load validation at 150% of rated capacity. Below is a comprehensive overview of standard specifications, with customization available to meet vessel-specific requirements per IACS Unified Requirements and SOLAS Chapter II-1 regulations.

| Parameter | Standard Range | Custom Options | Drive Type Compatibility | Compliance Notes |

|---|---|---|---|---|

| Pull Load | 50 kN – 3,000 kN | Up to 5,000 kN | Electric/Hydraulic | Tested per ISO 3822; 1.5x safety factor |

| Chain Diameter | 12.5 mm – 60 mm | 62 mm – 84 mm | Electric/Hydraulic | ISO 1704 stud link chain compliant |

| Drum Capacity | 150 m – 1,200 m | Project-specific | Electric/Hydraulic | Layer capacity adjustable |

| Operating Pressure | N/A | 160 – 350 bar | Hydraulic only | ASME B31.3 piping standards |

| Motor Power | 7.5 kW – 250 kW | Up to 400 kW | Electric only | IEC 60034-1; IP56/IP66 enclosure |

| Speed Range | 5 – 30 m/min | Variable | Both | ±5% tolerance at full load |

| Environmental Rating | -25°C to +55°C | Arctic (-45°C) | Both | ABS Guide for Arctic Operations |

Our systems integrate advanced features such as automatic chain tensioning, emergency disengagement mechanisms, and corrosion-resistant components treated with duplex coating (zinc-rich primer + polyurethane topcoat). Electric drive models utilize marine-grade copper windings with VFD compatibility for precise speed control, while hydraulic variants feature closed-circuit systems with thermal overload protection. All machinery incorporates fail-safe braking systems meeting ISO 15037-1 requirements, with static holding capacity at 1.5 times maximum working load.

Material selection adheres to DNVGL-SE-0132 guidelines, utilizing forged steel gears (AISI 4140/4340) and nodular cast iron drums. Control interfaces comply with IEC 60945 for EMC immunity and include remote operation capabilities via CAN bus or Ethernet protocols. Each unit undergoes 100-hour continuous load testing prior to shipment, with documentation including Material Test Reports (MTRs), Non-Destructive Testing (NDT) records, and classification society certificates. For export compliance, Hangzhou Star provides complete technical dossiers aligned with EU Marine Equipment Directive (MED) and U.S. Coast Guard Type Approval requirements.

As your export partner, we facilitate seamless global deployment through pre-shipment inspections, multilingual technical manuals, and on-site commissioning support. Contact our engineering team to discuss project-specific adaptations, including dual-windlass configurations or hybrid drive solutions for energy-efficient vessel operations. All specifications are subject to final design review based on vessel class, operational profile, and flag state regulations.

Shipbuilding Solutions

Comprehensive Deck Machinery Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers integrated deck machinery systems tailored for both new shipbuilding projects and marine repair operations. As a specialized marine equipment engineering and export provider, we focus on reliability, compliance, and rapid deployment to meet the demanding timelines of modern shipyards and vessel operators. Our expertise in ship deck machines ensures that clients receive engineered solutions that align with international maritime standards, including ISO, IEC, and classification society requirements from ABS, DNV, LR, and CCS.

Our product portfolio includes hydraulic and electric windlasses, mooring winches, anchor handling winches, deck cranes, and stern rollers—each designed for durability in harsh marine environments. For new construction, we collaborate closely with ship design teams to integrate deck machinery into the vessel’s overall system architecture, ensuring optimal performance, load compatibility, and space utilization. Our engineering team provides 3D modeling, load calculations, and interface documentation to streamline integration during the build phase.

In ship repair and retrofit scenarios, Star Marine offers fast-response technical support and replacement solutions. We maintain strategic inventory levels of critical components and standard models, enabling delivery within 4–6 weeks for most standard deck machinery units. Our global logistics network supports just-in-time delivery to major shipyards across Asia, the Middle East, and Europe, minimizing downtime during repair cycles.

All equipment is manufactured under stringent quality control procedures, with full material traceability and third-party inspection options available upon request. We provide comprehensive documentation packages, including operation manuals, maintenance guides, and certification dossiers, to support long-term serviceability.

Performance and Delivery Overview

| Parameter | Specification |

|---|---|

| Product Range | Windlasses, Mooring Winches, Anchor Winches, Deck Cranes, Stern Rollers |

| Power Options | Hydraulic, Electric, Electro-Hydraulic |

| Design Standards | ISO 3912, ISO 15927, DNVGL-SE-0202, ABS Marine Guide |

| Load Capacity Range | 50 kN to 3,000 kN (custom designs available) |

| Typical Lead Time – New Build | 8–12 weeks (based on customization level) |

| Typical Lead Time – Repair | 4–6 weeks (standard models) |

| Certification Options | ABS, DNV, LR, CCS, BV, RINA (on request) |

| Service Support | On-site commissioning, remote troubleshooting, spare parts supply |

We understand that delays in shipbuilding or dry-dock repairs directly impact operational costs. That is why Star Marine prioritizes responsiveness without compromising engineering integrity. Our export department is equipped to manage customs documentation, shipping coordination, and port delivery, ensuring a seamless supply chain from our Hangzhou facility to the global maritime market.

For shipyards and shipowners seeking a dependable partner in deck machinery, Hangzhou Star Marine Technology provides a complete turnkey solution—from design and manufacturing to installation support and after-sales service.

Packaging & Logistics

Packaging & Logistics for Ship Deck Machinery Export

Proper packaging and logistics execution are critical for ensuring the safe global delivery of marine deck machinery, which includes winches, windlasses, mooring systems, and associated control units. At Hangzhou Star Marine Technology, we implement rigorous, industry-standard packaging protocols designed to withstand the harsh maritime transport environment, prevent damage during handling, and comply strictly with international phytosanitary and shipping regulations. Our methodologies prioritize cargo integrity from factory dispatch through final vessel loading at Chinese ports.

All wooden packaging materials, including crates, dunnage, and skids, are manufactured exclusively from ISPM 15 certified lumber. This international standard mandates heat treatment (HT) to a minimum core temperature of 56°C for at least 30 minutes, eliminating pests and pathogens. Each wooden component bears the official ISPM 15 mark, clearly identifying the country of origin, producer code, and HT certification. This fumigation-free process ensures seamless customs clearance worldwide, avoiding costly delays or rejections at destination ports. Wooden crates are constructed with marine-grade plywood sheathing over robust timber frames, providing essential moisture resistance and structural rigidity for sensitive hydraulic and electrical components during ocean transit.

For heavier deck machinery units exceeding standard crate capacities or requiring frequent handling, we utilize custom-engineered steel pallet systems. These pallets feature reinforced I-beam structures, non-slip surfaces, and integrated lifting points conforming to ISO container handling standards. Steel pallets offer superior load distribution for equipment like大型锚绞车 (large anchor windlasses) and are fully reusable, aligning with sustainable logistics practices. Both packaging types incorporate extensive internal bracing, vibration-dampening materials, and desiccant packs to mitigate movement and condensation risks. All external surfaces receive weatherproof labeling with IMO-compliant stenciling, including cargo dimensions, gross weight, center of gravity indicators, and handling instructions.

The following table details our standard packaging specifications:

| Packaging Type | Dimensions Range (L x W x H) | Max Load Capacity | Key Features |

|---|---|---|---|

| ISPM 15 Wooden Crate | 1.5m x 1.2m x 1.0m to 6m x 2.4m x 2.8m | 2.5 – 15 metric tons | Heat-treated lumber, marine plywood sheathing, internal bracing, desiccant, weatherproof labeling |

| Steel Pallet System | 2.0m x 1.5m to 4.5m x 2.5m | 5 – 25 metric tons | Reinforced steel frame, integrated lifting lugs, non-slip deck, reusable design, corrosion-resistant coating |

Exports originate exclusively from the major deep-water ports of Ningbo-Zhoushan and Shanghai, leveraging their world-class infrastructure for heavy-lift cargo and direct access to global shipping lanes. Our Ningbo/Shanghai logistics team coordinates all pre-shipment activities, including terminal appointments, mandatory port security declarations (ISPS), and integration with mainline carrier schedules. We provide comprehensive documentation packages featuring the ISPM 15 certificate, packing list with net/gross weights per unit, cargo insurance, and SOLAS-compliant container weight verification (VGM). Rigorous pre-shipment inspections verify packaging integrity and securement before release to the terminal, ensuring compliance with carrier requirements and minimizing transit risks. This integrated approach guarantees that Hangzhou Star Marine Technology’s deck machinery arrives at its international destination in optimal condition, ready for immediate installation and commissioning.

Contact Star Marine

For global shipbuilders, shipowners, and marine equipment procurement officers seeking reliable, high-performance deck machinery solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted partner in the maritime industry. With years of engineering expertise and a commitment to innovation, quality, and after-sales support, we specialize in the design, manufacturing, and export of advanced ship deck machines tailored to meet international standards and the demanding conditions of marine operations.

Our product portfolio includes deck machinery such as mooring winches, anchor windlasses, cargo cranes, towing winches, and deck cranes—each engineered for durability, precision control, and seamless integration into vessel systems. Whether your project involves new vessel construction or retrofitting existing fleets, our engineering team ensures customized configurations that align with vessel specifications, load requirements, and operational environments.

At Hangzhou Star Marine, we understand that selecting the right deck machinery is critical to vessel safety, efficiency, and compliance. That’s why we offer end-to-end technical consultation—from initial concept and load analysis to installation guidance and commissioning support. Our products are manufactured under strict ISO 9001-certified quality management systems and comply with major classification society rules, including CCS, ABS, DNV, LR, and BV.

To ensure a streamlined procurement process, we maintain efficient production cycles, real-time project tracking, and global logistics coordination, enabling on-time delivery to ports worldwide. Our after-sales service network provides technical assistance, spare parts supply, and field support, ensuring long-term operational reliability.

For personalized assistance with product selection, technical specifications, or quotation requests, we invite you to contact our Product Manager, Kacher YE, directly. With in-depth knowledge of deck machinery applications and export procedures, Mr. Ye serves as your dedicated point of contact to guide you through every phase of your procurement journey.

Below are key contact details and response time expectations:

| Contact Information | Details |

|---|---|

| Name | Kacher YE |

| Position | Product Manager – Deck Machinery |

| [email protected] | |

| Company | Hangzhou Star Marine Technology Co., Ltd. |

| Response Time | Within 4 business hours (GMT+8) |

| Languages Supported | English, Chinese, Basic French |

| Service Scope | Technical Inquiry, Quotation, OEM/ODM Support, After-Sales Coordination |

We welcome inquiries from distributors, shipyards, and marine engineering firms seeking high-quality deck machinery backed by responsive service and technical excellence. Partner with Hangzhou Star Marine Technology and experience the difference of working with a manufacturer that prioritizes performance, reliability, and customer satisfaction.

Contact Kacher YE today to discuss your deck machinery requirements and discover how our engineered solutions can enhance your vessel’s operational capability.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160