Ship Outfittings – Marine Solution Guide 2025

Content Navigation

Marine Insight: Ship Outfittings

Marine Industry Demand: Ship Outfittings Criticality and Strategic Sourcing Value

Ship outfittings constitute the fundamental hardware infrastructure essential for safe vessel operation, crew protection, and regulatory compliance across all maritime sectors. These mission-critical components, ranging from mooring and anchoring systems to deck hardware and lifesaving appliance foundations, directly impact vessel integrity and personnel safety during routine operations and emergency scenarios. Failure of key outfittings such as bollards, chocks, or davit systems can lead to catastrophic incidents including uncontrolled drifting, cargo loss, structural damage, or compromised evacuation capabilities. Consequently, international conventions like SOLAS and classification society rules (e.g., DNV, ABS, LR) mandate stringent design, material, and testing standards for all outfittings. Compliance is non-negotiable; substandard equipment poses unacceptable risks to human life, the marine environment, and significant financial liabilities through detentions, fines, or insurance invalidation. The global fleet’s continuous renewal and stringent safety audits drive consistent, high-volume demand for certified outfittings meeting exacting technical specifications.

Sourcing outfittings from Hangzhou Star Marine Technology delivers significant cost-effectiveness without compromising on safety or quality, a critical advantage in today’s competitive maritime market. Our vertically integrated manufacturing model within China’s advanced industrial ecosystem enables substantial economies of scale and optimized production efficiency. Unlike suppliers reliant on fragmented subcontracting, Star Marine maintains rigorous in-house control over the entire process – from certified raw material procurement (traceable steel alloys) through precision forging, machining, non-destructive testing (NDT), surface treatment, and final inspection. This direct oversight eliminates multiple markup layers while ensuring every component adheres strictly to ISO 3834 (welding quality), ISO 9001 (quality management), and relevant IMO/SOLAS requirements. Our strategic location provides access to high-grade domestic materials and skilled labor at globally competitive rates, translating into demonstrable cost savings for clients without sacrificing the metallurgical integrity or dimensional accuracy demanded by classification societies. The table below illustrates representative outfittings where Star Marine delivers certified performance at optimal value.

| Product Category | Key Material Specification | Typical Working Load Limit (WLL) | Primary Compliance Standards |

|---|---|---|---|

| Mooring Bitts | Forged ASTM A668 Class D | 500 kN – 3000 kN | ISO 3911, IACS UR S20 |

| Deck Cargo Eyes | Forged ASTM A105 | 100 kN – 1500 kN | ISO 1161, SOLAS II-1/3-8 |

| Lifeboat Davit Fittings | Forged ASTM A540 B21 | 50 kN – 200 kN | LSA Code Ch. IV, ISO 9090 |

The inherent safety margin and longevity of properly engineered outfittings directly reduce a vessel’s total cost of ownership through minimized maintenance, avoided downtime, and prevention of costly accidents. Star Marine’s commitment to engineering excellence, coupled with transparent pricing derived from efficient domestic manufacturing and logistics, positions us as the strategic partner for shipyards and operators prioritizing both uncompromised safety and operational cost efficiency. Trust in outfittings is not merely a procurement decision; it is a foundational element of maritime risk management, where Star Marine delivers proven reliability and exceptional value.

Technical Specs & Approval

Hangzhou Star Marine Technology Co., Ltd. provides high-performance marine outfittings designed to meet the rigorous demands of commercial, offshore, and naval vessel operations. Our ship outfittings are engineered for reliability, structural integrity, and long-term resistance to harsh maritime environments. These components include ladders, gratings, handrails, access hatches, and deck fittings, all manufactured in accordance with international maritime standards including ISO 15848, SOLAS, and DNV-GL guidelines. Emphasis is placed on material selection, dimensional precision, and watertight performance to ensure safe and efficient vessel operation.

Material selection is a critical factor in the performance and longevity of marine outfittings. We offer products fabricated from marine-grade aluminum alloys (5083, 5086, 6061-T6) and structural steel (A36, Q235B) with anti-corrosive coatings. Aluminum variants are preferred for weight-sensitive applications such as superstructures and passenger vessels, offering excellent strength-to-weight ratios and natural corrosion resistance. Steel-based outfittings are utilized in high-load environments, including cargo holds and engine rooms, where mechanical strength and impact resistance are paramount. All steel components undergo hot-dip galvanization or epoxy/polyurethane coating systems to ensure durability in saltwater conditions.

Watertight integrity is essential in compartments requiring pressure or environmental isolation. Our watertight doors, hatches, and access panels are designed with double-sealed gasket systems compliant with IP67 and IP68 standards, ensuring zero water ingress under static head pressures up to 5 meters. Gaskets are manufactured from EPDM or nitrile rubber, selected based on chemical exposure and temperature range. All watertight fittings undergo hydrostatic testing at 1.5 times their rated pressure during quality control.

Dimensional accuracy ensures seamless integration with shipboard structures. Standard sizes are maintained across product lines, with customization available to meet specific design drawings or class society requirements. Tolerances are held within ±1.5 mm for linear dimensions and ±1° for angular alignments in welded assemblies. This precision facilitates efficient installation and alignment during vessel outfitting and retrofit projects.

Below is a summary of key technical parameters for our standard marine outfittings:

| Parameter | Aluminum Outfittings | Steel Outfittings | Watertight Components |

|---|---|---|---|

| Base Material | 5083/5086 H321, 6061-T6 | Q235B, A36 with HDG coating | 316 Stainless Steel / Q235B |

| Corrosion Protection | Anodized or powder-coated | Hot-dip galvanized | Epoxy primer + PU topcoat |

| Operating Temperature | -40°C to +80°C | -40°C to +70°C | -30°C to +90°C |

| Watertight Rating | N/A (drainage design) | N/A | IP67 / IP68 (up to 5m H2O) |

| Standard Compliance | ISO 15848, SOLAS Ch.II-1 | DNV-GL, ABS, CCS | IMO A.746(18), EN 1027 |

| Dimensional Tolerance | ±1.5 mm | ±1.5 mm | ±1.0 mm |

| Load Capacity (Handrails) | 1.2 kN/m horizontal | 1.5 kN/m horizontal | 1.0 kN/m (sealed panels) |

All products undergo rigorous quality assurance protocols, including ultrasonic testing for weld integrity, dimensional inspection, and visual examination per IACS guidelines. Hangzhou Star Marine Technology ensures every marine outfitting component supports safe, compliant, and efficient vessel construction and operation.

Shipbuilding Solutions

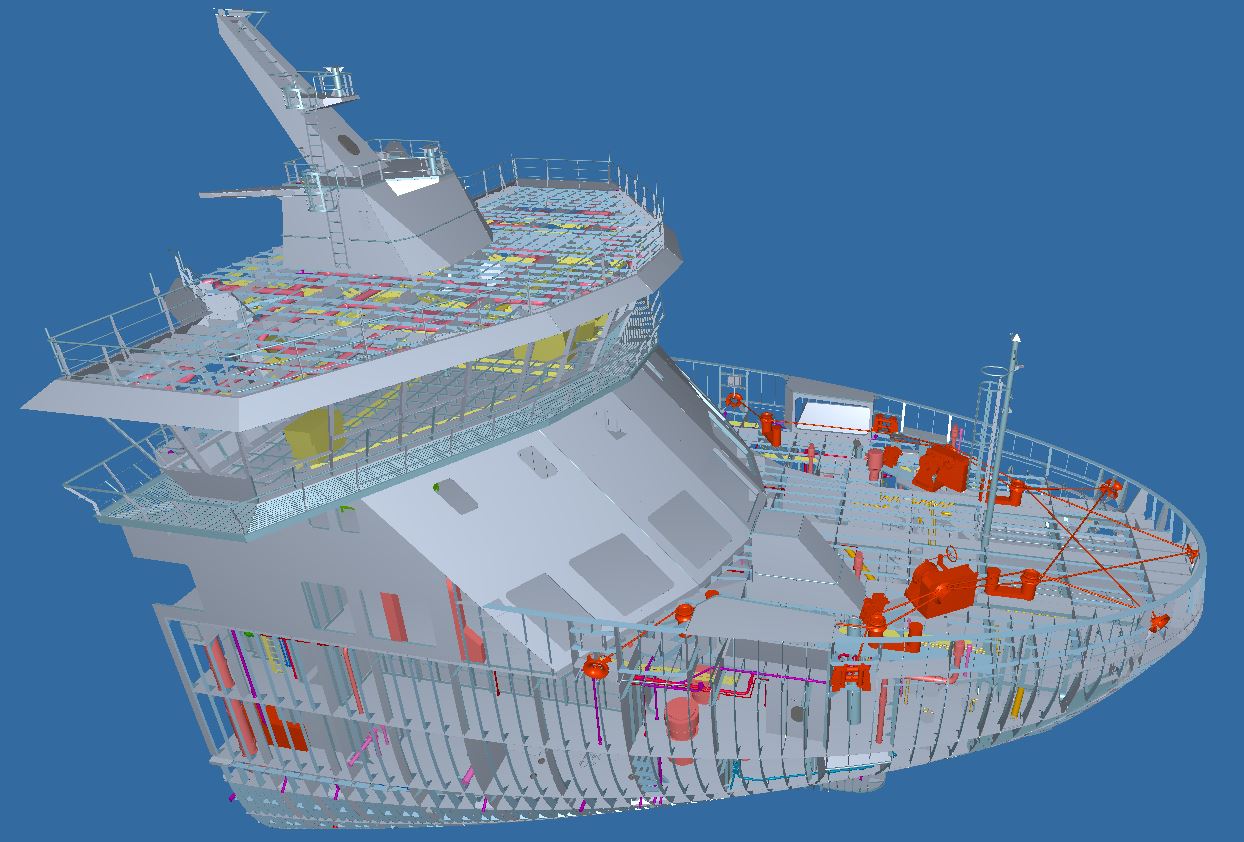

Comprehensive Ship Outfitting Solutions for New Construction and Repair

Hangzhou Star Marine Technology Co. Ltd. delivers integrated marine outfittings solutions engineered to streamline vessel construction and complex repair projects globally. Our expertise spans the full spectrum of ship outfitting requirements, providing shipyards and operators with a single-source partner for critical hardware, ensuring project timelines are met without compromising on quality or regulatory compliance. We understand the intense pressure on modern shipbuilding and repair schedules; therefore, our core mission is to eliminate supply chain bottlenecks through proactive engineering support and rapid execution.

For new build programs, Star Marine provides meticulous coordination from the early design phase. Our engineering team collaborates directly with naval architects and shipyard project managers to review specifications, offer value engineering suggestions for outfitting packages, and ensure seamless integration of components like deck machinery, hatch covers, and accommodation fittings. We manage the entire procurement lifecycle, sourcing high-grade materials compliant with ISO, SOLAS, and class society requirements (LR, DNV, ABS, CCS, etc.), and oversee stringent factory acceptance testing. This integrated approach prevents costly rework and delays during critical path installation stages.

Our commitment extends equally to the demanding environment of vessel repair and conversion. Recognizing that downtime equates to significant revenue loss, Star Marine maintains strategic global inventory hubs and leverages established logistics networks for urgent spare parts and replacement outfittings. Whether it’s emergency mooring equipment, damaged deck hardware, or obsolete component replacement, our dedicated repair support desk provides 24/7 technical consultation and rapid dispatch. We specialize in reverse engineering for legacy systems, ensuring compatibility and minimizing vessel turnaround time in dry dock.

The cornerstone of our service is Fast Response Execution. We achieve this through dedicated project management, pre-vetted manufacturing partners, and a focus on critical path items. Our global logistics framework prioritizes air freight readiness for urgent needs and optimizes sea freight consolidation for larger projects, providing real-time shipment tracking. This operational agility directly translates to reduced vessel idle time for our clients.

Key outfittings categories we supply with documented technical specifications include:

| Product Category | Typical Materials | Key Compliance Standards | Common Applications |

|---|---|---|---|

| Deck Machinery | Forged Steel, Marine Grade Aluminum | ISO 3911, DNV-ST-N001 | Windlasses, Mooring Winches, Capstans |

| Hatch Covers & Sealing | High-Tensile Steel, Rubber Compounds | ISO 1161, SOLAS Ch VI | Container Ship Hatches, General Cargo |

| Mooring & Anchoring | Grade E36 Steel, Synthetic Fiber | ISO 3912, OCIMF Mooring | Bollards, Fairleads, Anchor Windlasses |

| Accommodation Outfitting | Stainless Steel, Marine Plywood, Composites | ISO 8818, IMO FTP Code | Staircases, Handrails, Interior Fittings |

| Piping & Valves | Duplex SS, Bronze, Carbon Steel | ISO 15748, MSS SP-61 | Ballast, Bilge, Deck Wash Systems |

Hangzhou Star Marine Technology is your strategic partner for dependable, efficient, and fully compliant marine outfittings. We combine deep technical knowledge with an unwavering focus on rapid delivery, empowering shipyards and owners to execute new builds and repairs with confidence and schedule certainty. Contact our Export Management team for immediate project support and tailored solution proposals.

Packaging & Logistics

Packaging & Logistics for Marine Outfittings – Export Guidelines

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine outfittings are packaged to meet international shipping standards and protect equipment during transit. Our packaging protocols are designed to comply with global regulatory requirements, prevent damage during handling, and support efficient logistics operations for shipments originating from Ningbo and Shanghai ports—two of China’s most strategic maritime export hubs.

For sensitive and high-value marine outfittings such as deck machinery components, piping systems, ventilation units, and navigational hardware, we utilize ISPM 15 certified wooden cases. These wooden crates are constructed from heat-treated hardwood or plywood, ensuring compliance with International Standards for Phytosanitary Measures No. 15 (ISPM 15), which is mandatory for all wooden packaging materials entering most countries. Each wooden case is marked with the official ISPM 15 stamp, indicating treatment and compliance. The cases are internally lined with moisture-resistant barrier films and include shock-absorbing padding where necessary to safeguard against vibration, humidity, and impact during ocean freight.

In applications where durability and reusability are critical—especially for heavy-duty items such as anchor windlasses, hatch cover components, or large valve assemblies—we employ steel pallets. These robust platforms provide superior load-bearing capacity and are ideal for unitizing bulky or irregularly shaped outfittings. Steel pallets are weld-constructed from high-tensile carbon steel, hot-dip galvanized for corrosion resistance, and designed to be compatible with forklifts and container handling equipment. Unlike wooden alternatives, steel pallets eliminate the risk of pest infestation and do not require fumigation, streamlining customs clearance in destination countries.

All packaged marine outfittings are labeled with durable, weather-resistant identification tags indicating product details, order number, handling instructions, and destination port. We coordinate closely with certified freight forwarders to ensure seamless multimodal transport from our facility to the port, followed by container loading under supervision. Shipments are typically routed through Ningbo-Zhoushan Port or Shanghai Port, both offering extensive global connectivity, high throughput capacity, and advanced container terminal operations.

Our logistics team monitors each shipment in real time, providing clients with tracking updates and documentation packages including packing lists, certificates of origin, and compliance statements. This end-to-end control ensures that marine outfittings arrive at their destination in optimal condition, ready for immediate integration into vessel construction or retrofit projects.

The following table summarizes our standard packaging methods and specifications:

| Packaging Type | Material Specification | Compliance Standard | Typical Use Case | Reusability |

|---|---|---|---|---|

| Wooden Cases | Heat-treated plywood or hardwood | ISPM 15 | Precision instruments, control panels | Limited |

| Steel Pallets | Hot-dip galvanized carbon steel | None required | Heavy machinery, large structural parts | High |

By adhering to these rigorous packaging and logistics standards, Hangzhou Star Marine Technology ensures reliability, regulatory compliance, and customer satisfaction in every export shipment.

Contact Star Marine

Contact Star Marine for Precision Marine Outfittings Solutions

At Hangzhou Star Marine Technology Co. Ltd, our engineering and export teams operate at the intersection of maritime innovation and global supply chain excellence. With over 15 years of specialization in marine outfittings, we deliver engineered solutions that meet stringent SOLAS, IMO, and class society standards—including DNV, ABS, and CCS. Our commitment extends beyond component supply; we provide lifecycle support from initial specification validation to post-installation technical oversight. For shipyards, naval architects, and vessel operators navigating complex procurement landscapes, partnering with Star Marine ensures compliance, durability, and operational efficiency in every outfittings package.

Technical complexity demands precise collaboration. Whether your project involves high-capacity deck machinery for offshore support vessels or corrosion-resistant piping systems for LNG carriers, our product management team de-risks procurement through rigorous material traceability, FAT coordination, and seamless customs documentation. We recognize that outfittings failures cascade into costly delays—our engineering-led approach mitigates this through proactive design reviews and real-time technical validation against your vessel’s schematics. Below outlines core outfittings categories where our expertise delivers measurable project advantages:

| Product Category | Technical Scope | Key Applications |

|---|---|---|

| Deck Machinery Systems | Hydraulic anchor windlasses (100–500 kN pull) | Bulk carriers, Ro-Ro vessels |

| Cargo Handling Equipment | Telescopic cranes (10–50 MT SWL), hatch covers | Container ships, general cargo |

| Piping & Valve Solutions | Duplex SS piping (DN15–DN600), cryogenic valves | Tankers, LNG carriers, chemical ships |

| Safety & Mooring Systems | Emergency towing pendants, synthetic mooring lines | All vessel types, port infrastructure |

Initiate your outfittings procurement with a technical consultation led by Kacher YE, our dedicated Product Manager for Marine Outfittings. Kacher combines naval architecture expertise with hands-on export execution across 32 countries, ensuring specifications align with both operational requirements and destination regulatory frameworks. His team specializes in translating complex RFQs into actionable engineering packages—reducing lead times by 18% through optimized logistics routing and pre-shipment verification protocols.

Do not navigate outfittings procurement without expert validation. Contact Kacher YE directly at [email protected] to:

Receive a project-specific technical compliance dossier within 24 business hours

Schedule a virtual design review with our marine engineers

Access class-approved material test certificates and 3D CAD models

Clarify customs tariff classifications for your target market

Hangzhou Star Marine Technology operates from a 12,000 m² ISO 9001:2015-certified facility with in-house CNC machining, non-destructive testing, and hydraulic testing bays. Every outfittings component undergoes pressure testing to 1.5x working pressure and salt-spray validation per ASTM B117. When project timelines tighten or specifications evolve, Kacher’s team implements rapid engineering change orders without compromising certification integrity. For shipyards under construction deadlines or operators managing dry-dock schedules, this agility prevents costly standstill periods.

Elevate your outfittings procurement from transactional sourcing to engineered partnership. Email Kacher YE today with your vessel specifications, class requirements, and target delivery window. Our technical export desk will respond with a feasibility assessment, preliminary quotation, and recommended action plan—ensuring your outfittings integration proceeds with maritime-grade precision. In an industry where component reliability defines vessel safety, trust Star Marine’s engineering rigor to secure your project’s success.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160