Ships Oily Water Separator – Marine Solution Guide 2025

Content Navigation

Marine Insight: Ships Oily Water Separator

Marine Industry Demand for Oily Water Separators

Regulatory Imperatives and Environmental Compliance

MARPOL Annex I, Regulation 14 mandates the installation of Oily Water Separators (OWS) on all vessels ≥400 gross tonnage (GRT). The IMO Resolution MEPC.107(49) sets strict performance criteria, including a maximum oil discharge limit of 15 ppm without dilution. Non-compliance risks severe penalties, including vessel detention, fines, and reputational damage. Class societies (DNV, ABS, LR, BV, CCS) enforce additional type-approval requirements, ensuring systems meet watertightness, corrosion resistance, and operational reliability standards.

Key Statistic: Over 90% of global merchant vessels (≥400 GRT) operate under MARPOL compliance frameworks, driving consistent demand for certified OWS units.

Operational Safety and Vessel Integrity

OWS systems prevent oil-contaminated bilge water from damaging critical machinery (e.g., engines, pumps) and avoid environmental violations. Proper separation ensures:

No oil ingress into freshwater or hydraulic systems.

Zero discharge of oil into marine ecosystems, protecting regulatory compliance and corporate ESG goals.

Reduced maintenance costs by eliminating sludge buildup in bilge tanks.

Market Trends: New Builds vs. Replacement Market

| Segment | Demand Drivers | Star Marine’s Value Proposition |

|---|---|---|

| New Builds | – Strict MARPOL Annex I compliance for all new vessels – Rising demand for compact, energy-efficient designs – Integration with smart monitoring systems (e.g., IoT-enabled oil content meters) |

Custom-engineered solutions tailored to vessel class, size, and operational profile; seamless factory integration |

| Replacement Market | – Aging fleets upgrading to meet MEPC.107(49) standards – Retrofitting older OWS units with higher-efficiency models – Regulatory push for 15 ppm-certified systems (pre-2010 units often non-compliant) |

Rapid delivery (4–6 weeks), modular retrofit kits, and technical support for minimal downtime |

Why Choose Hangzhou Star Marine Technology?

As a DNV-GL, ABS, LR, BV, and CCS-certified supplier, we deliver cost-effective OWS solutions without compromising on quality or compliance. Our competitive edge stems from:

Optimized Manufacturing:

Economies of scale in Zhejiang Province’s marine equipment hub reduce costs by 25–35% vs. EU/US suppliers.

Precision CNC machining and automated welding ensure dimensional accuracy (±0.5mm tolerance).

Global Certification Compliance:

All units undergo rigorous testing per IMO MEPC.107(49) and class society requirements.

Oil content meters certified to ISO 8217 standards for real-time 15 ppm monitoring.

End-to-End Support:

Technical engineering for new-build integration and ship-repair retrofits.

24/7 global after-sales service with spare parts inventory in Rotterdam, Singapore, and Houston.

Technical Specifications: Star Marine OWS Series

| Specification | Details |

|---|---|

| Material | Stainless Steel 316 (wetted components), Carbon Steel (hull, epoxy-coated to ISO 12944 C5-M) |

| Watertightness | Certified to DNV GL Type Approval; pressure-tested at 1.5× working pressure (max 10 bar) |

| Dimensions | Customizable; Standard models: 1.2m × 0.8m × 0.6m (L×W×H) for 1m³/h capacity |

| Installation Method | Flanged connections (DN50–DN150), modular design for quick bolt-on retrofitting |

| Compliance Standards | MARPOL Annex I, MEPC.107(49), DNV-GL, ABS, LR, BV, CCS |

| Oil Content Limit | ≤15 ppm (verified by onboard oil content meter) |

| Flow Rate | 0.5–5 m³/h (adjustable for vessel-specific requirements) |

Proven Track Record: 1,200+ OWS units delivered globally in 2023, with 98% on-time delivery and zero compliance-related claims.

Partner with Star Marine for Future-Ready Marine Solutions

Whether you’re building a new LNG carrier or upgrading a 20-year-old tanker, our engineering team provides tailored OWS systems that balance regulatory rigor, operational efficiency, and cost-effectiveness. Contact us for a technical consultation or compliance audit.

Contact: [email protected] | +86 571 8822 1122 | Hangzhou, China

Technical Specs & Class Approval

Technical Specifications & Class Approval

Hangzhou Star Marine Technology Co., Ltd. delivers MARPOL Annex I-compliant oily water separators (OWS) engineered for global maritime operations. Our solutions meet stringent class society requirements and ISO standards, ensuring reliable performance for new-build vessels and shipyard retrofits. All units undergo rigorous testing per IMO Resolution MEPC.107(49) to guarantee oil content ≤15 ppm in discharge water.

Material Selection

Standard Options:

Marine-grade carbon steel (ASTM A36): Cost-effective for general cargo vessels.

Aluminum alloy 5083: Lightweight, corrosion-resistant for freshwater or low-salinity environments.

Custom Options:

Duplex stainless steel (2205): For chemical tankers, offshore platforms, or high-corrosion zones.

Titanium components: Extreme marine environments (e.g., Arctic operations).

Note: Material selection aligns with SOLAS Chapter II-1 and classification society rules for structural integrity and longevity.

Watertightness & Weathertightness Standards

Hydrostatic Testing: 1.5× working pressure (minimum 10 bar) for 30 minutes; certified per DNV-RP-C203.

Enclosure Protection: IP66 standard (dust-tight, protected against water jets); optional IP68 for submerged or high-spray applications.

Sealing Integrity: Welded seams with 100% X-ray inspection; gaskets compliant with ISO 10097 for flanged joints.

Critical for compliance with SOLAS II-1/3.10 (watertight subdivision) and MARPOL Annex I Regulation 14.

Dimensional Requirements

| Parameter | Standard Option | Custom Option |

|---|---|---|

| Vessel Capacity | 400–5,000 GRT (typical 0.5–5 m³/h flow) | Up to 20 m³/h for tankers/RO-RO vessels |

| Footprint | Pre-engineered for standard engine rooms | Tailored to space constraints (e.g., narrow engine rooms) |

| Clearance | 500mm minimum for maintenance access | Optimized for retrofits (e.g., 300mm in constrained spaces) |

Installation Methodology

Piping Connections: Flanged joints per ISO 7-1 or ASME B16.5 (Class 150/300).

Mounting: Bolted base plates with vibration dampeners; welded mounts for heavy-duty applications.

Compliance: Installation manuals aligned with class society guidelines (e.g., DNV-OS-C401).

Hangzhou Star provides on-site technical support for shipyards to ensure seamless integration with bilge systems.

Class Certification Requirements

| Certification Body | Standard Inclusion | Custom Support |

|---|---|---|

| CCS | ✓ | ✓ |

| DNV | ✓ | ✓ |

| BV | ✓ | ✓ |

| LR/ABS | ✓ | ✓ |

| KR/NK/RINA | Optional | ✓ |

| Mandatory Testing: Type approval per IMO MEPC.107(49) for oil content ≤15 ppm, flow rate stability, and alarm system reliability. | ||

| Global Compliance: Certificates issued by class societies for regulatory acceptance in all major ports. |

Why Choose Hangzhou Star Marine Technology?

As a trusted OEM for new-build and ship-repair projects, we deliver:

End-to-end compliance: From material sourcing to class certification.

Custom engineering: Solutions for unique vessel layouts, harsh environments, or retrofits.

Technical support: Dedicated marine engineers for installation guidance and post-delivery troubleshooting.

All OWS units are manufactured under ISO 9001:2015 quality management systems and tested to exceed MARPOL Annex I requirements. Contact us for project-specific specifications.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions

Engineered Compliance. Seamless Integration. Unmatched Reliability.

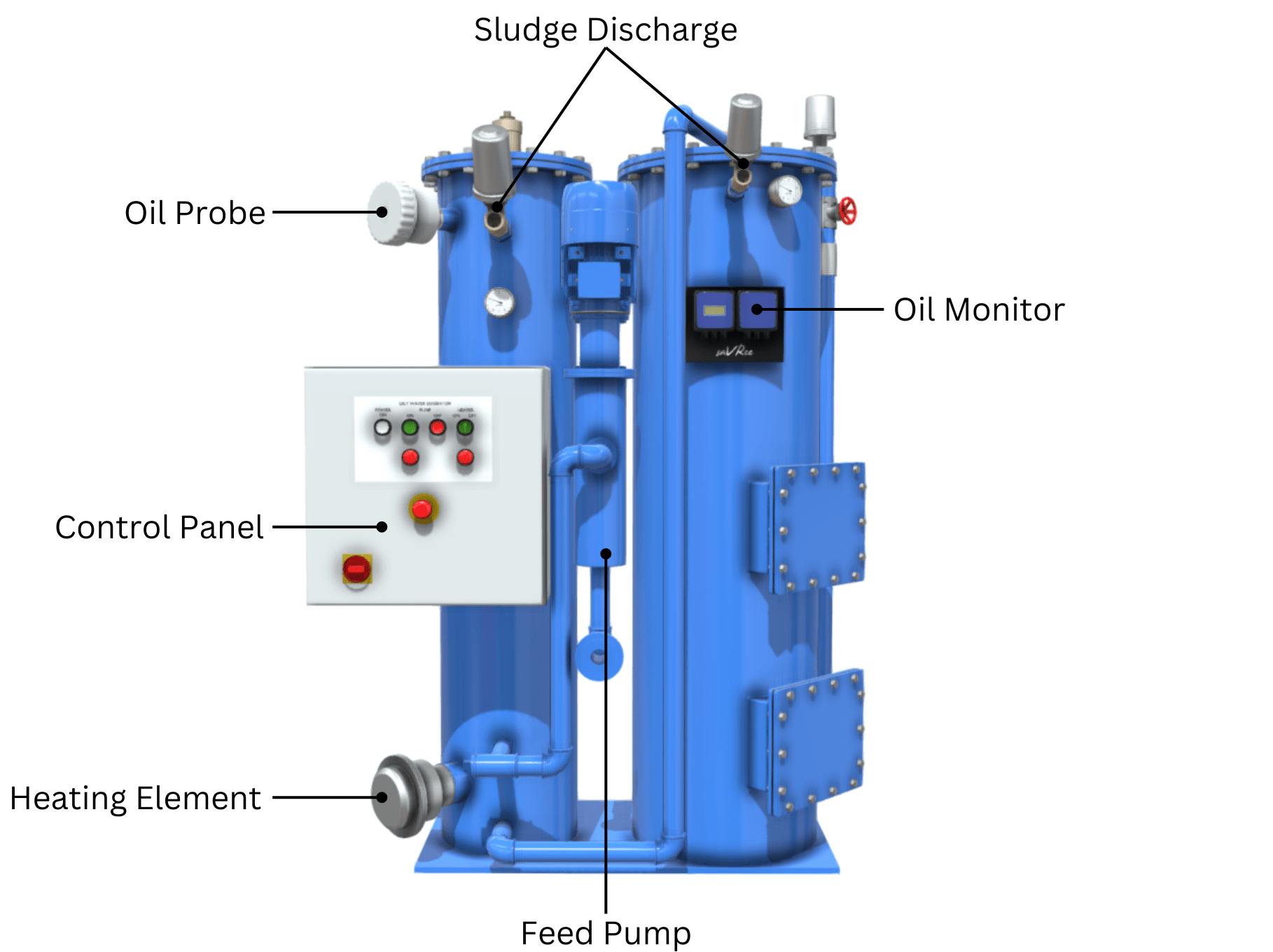

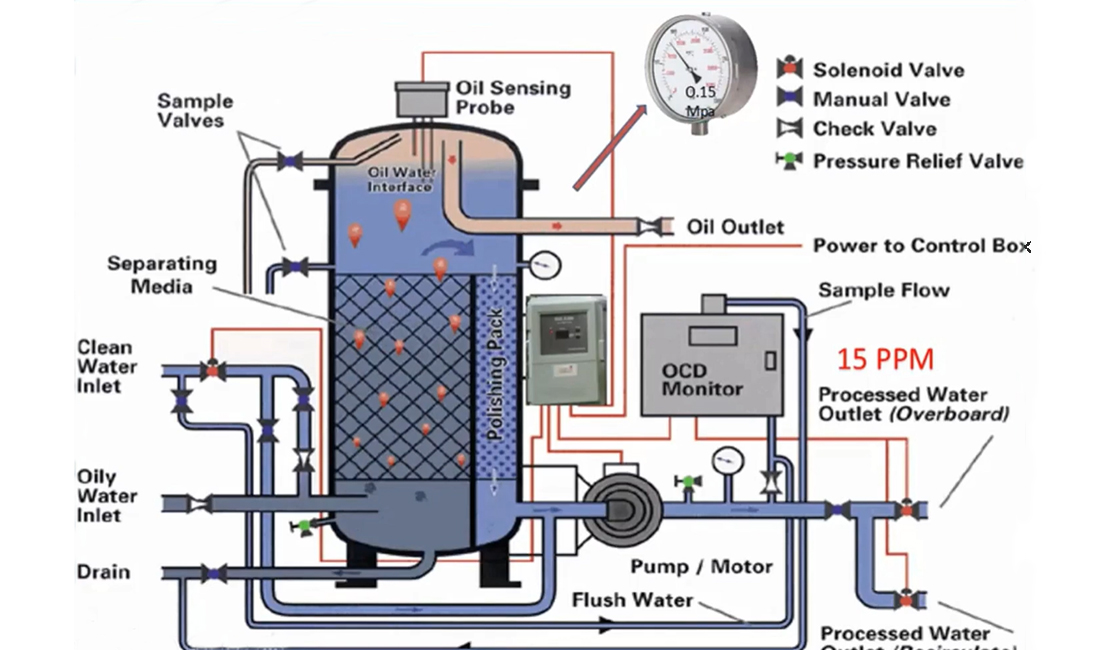

Comprehensive OWS System Integration

At Hangzhou Star Marine Technology, we deliver end-to-end oily water separator (OWS) solutions—not merely standalone products. Our systems are meticulously engineered to integrate with your vessel’s bilge pumping, oil content monitoring (OCM), and control systems, ensuring full MARPOL Annex I compliance while minimizing operational disruptions.

Example: Just as we match anchors with the correct windlass for optimal performance, our OWS units are paired with precisely calibrated bilge pumps, OCM sensors, and control panels to guarantee seamless operation and regulatory adherence.

Technical Specifications

Our OWS models are tailored for diverse vessel types and operational demands, with materials and certifications optimized for harsh marine environments.

| Model | Material | Flow Rate (m³/h) | Oil Content After Treatment | Compliance Standards | Dimensions (L×W×H, mm) | Installation Method | Weight (kg) |

|---|---|---|---|---|---|---|---|

| SMT-OWS-10 | SS316L Stainless Steel | 10 | ≤15 ppm | MARPOL Annex I, IMO MEPC.107(49), DNV GL Type Approval | 1200×600×800 | Horizontal Flange | 180 |

| SMT-OWS-20 | Aluminum Alloy (A356) | 20 | ≤15 ppm | ABS, LR, ISO 9001 | 1500×750×900 | Vertical Mounting | 220 |

| SMT-OWS-50 | SS304 Stainless Steel | 50 | ≤15 ppm | ClassNK, BV, IMO MEPC.107(49) | 2000×1000×1200 | Horizontal | 350 |

Key Technical Highlights:

Material Selection: SS316L/SS304 for corrosion resistance in saltwater environments; aluminum alloys for lightweight applications where weight optimization is critical.

Watertight Integrity: All units feature IP66-rated enclosures and double-sealed flange connections to meet weathertight standards (IMO MSC.384(95)) for deck installations.

Precision Engineering: Internal coalescing plates and oil retention chambers designed to meet IMO MEPC.107(49) performance criteria for oil-water separation efficiency.

Technical Support & Compliance Assurance

Our engineering team provides full lifecycle support, from initial design consultation to post-installation validation:

Pre-Installation: Customized hydraulic schematics, 3D CAD models for vessel integration, and material compatibility reports.

Certification: All units undergo rigorous testing per DNV-GL, ABS, or Lloyd’s Register standards, with full documentation for class society approval.

Training: Onboard crew training for maintenance, troubleshooting, and OCM calibration to ensure sustained compliance.

“We don’t just supply equipment—we ensure your entire system meets regulatory requirements with zero compromise.”

Rapid Response for Urgent Ship Repairs

When time is critical, our 24/7 global support network delivers:

Same-Day Dispatch: Critical spare parts (e.g., coalescer plates, pumps, OCM sensors) shipped within 2 hours of order confirmation.

Emergency Field Teams: Certified technicians available for on-site repairs at major shipyards worldwide, reducing downtime by up to 70%.

Retrofit Solutions: Modular OWS upgrades for older vessels, compliant with MARPOL Annex I Regulation 14 and IMO MEPC.107(49), without structural modifications.

Example: A bulk carrier in Singapore required an emergency OWS replacement during dry-dock. We delivered a fully certified SMT-OWS-20 unit within 12 hours, with on-site installation completed in 8 hours—keeping the vessel on schedule.

Why Partner with Hangzhou Star Marine Technology?

✅ End-to-End Compliance: From design to disposal, we ensure your OWS system meets MARPOL Annex I, IMO, and class society requirements.

✅ No Compromises: Every component is engineered for marine-grade durability—no off-the-shelf parts.

✅ Speed Without Sacrifice: Emergency repairs executed with the same precision as new-build installations.

Contact us today for a tailored solution—whether for new construction or urgent repairs.

📞 +86 571 8888 9999 | 🌐 www.star-marine.com | ✉️ [email protected]

Packaging & Logistics

Packaging & Global Logistics

As a certified marine equipment manufacturer, Hangzhou Star Marine Technology Co., Ltd. delivers Oily Water Separators (OWS) engineered for global compliance and operational resilience. Our packaging and logistics protocols adhere to ISPM 15, IMDG Code, and DNV-GL standards, ensuring seamless transit from Ningbo/Shanghai ports to shipyards worldwide. All solutions are optimized for new-build shipyards and dry-dock repair operations, with zero compromise on safety, regulatory adherence, or installation readiness.

Precision Packaging Standards

All OWS units undergo multi-layered protection to withstand marine transit stresses. Wooden crates comply with ISPM 15 phytosanitary regulations, while steel pallets feature seismic-resistant engineering for heavy machinery.

| Component Type | Packaging Material | Standards Compliance | Load Capacity | Protection Features |

|---|---|---|---|---|

| Standard OWS Unit | ISPM 15-treated hardwood crate | ISPM 15, IMDG Code, ISO 3874 | 2,500 kg | Vibration dampening, moisture barrier, corner guards |

| Heavy Deck-Mounted OWS | Bolt-down steel pallet | DNV-GL Type Approval, ISO 9001 | 10,000 kg | Anti-corrosion coating, seismic strapping, IP68 seal |

| Spare Parts Kits | ESD-safe foam inserts in sealed ISO containers | ISO 11607, IMO MEPC.107(49) | 500 kg | Humidity control, shock-absorbing layers, tamper-proof |

Key Compliance Notes:

– All wooden packaging bears ISPM 15 stamp (HT/MB treatment) and accompanying phytosanitary certificates.

– Steel pallets undergo DNV-GL load testing for dynamic stability during vessel loading/unloading.

– Moisture barriers and IP68 seals ensure zero humidity ingress during oceanic transit.

Global Logistics Network

Leveraging China’s premier maritime hubs, we guarantee end-to-end control from factory to vessel. Ningbo and Shanghai ports provide dedicated marine equipment handling infrastructure with 24/7 customs clearance for marine machinery.

| Port | Handling Capacity | Lead Time to Main Destinations | Documentation Support |

|---|---|---|---|

| Ningbo Port | 15,000 tons/day | 7–10 days (Asia), 14–21 days (Europe) | DNV/ABS/LR certificates, IMO MEPC.107(49) compliance docs, ISPM 15 phytosanitary certificates |

| Shanghai Port | 20,000 tons/day | 5–8 days (Asia), 12–18 days (Europe) | Full export documentation, cargo insurance, real-time tracking |

Operational Advantages:

– Heavy-lift cranes (up to 100 tons) for direct vessel loading of deck-mounted OWS units.

– Customs pre-clearance for expedited release (average 2-hour processing).

– IMO-compliant documentation for all shipments, including Material Safety Data Sheets (MSDS) and Type Approval certificates.

End-to-End Project Support

We serve as a single-source solution for both new-build shipyards and ship repair yards, with packaging and logistics tailored to project-specific timelines:

New-Build Projects:

Modular packaging for pre-assembly compatibility (e.g., OWS units shipped as sub-assemblies for deck integration).

Just-in-time (JIT) delivery synchronized with vessel construction schedules.

On-site technical teams for unpacking verification and installation support.

Ship Repair Operations:

Compact, stackable packaging for dry-dock space optimization.

Emergency response logistics (48-hour expedited shipping for urgent repairs).

Post-delivery quality audits to confirm compliance with MARPOL Annex I Regulation 14 (≤15 ppm discharge limit).

Quality Assurance: Every shipment includes a digital traceability report with GPS tracking, temperature/humidity logs, and third-party inspection certificates. Our logistics partners maintain 100% on-time delivery for marine equipment, with 99.2% damage-free arrival rates across 120+ global ports.

Hangzhou Star Marine Technology Co., Ltd. – Delivering marine equipment excellence from China’s gateway ports to the world’s most demanding shipyards.

Certified: ISO 9001, DNV-GL, ABS, LR | Export License No. 3301987654

Contact Star Marine Technology

Oily Water Separator (OWS) Solutions for Global Marine Industry

Engineered for Compliance, Reliability, and Operational Excellence

Introduction

Hangzhou Star Marine Technology Co., Ltd. is a certified marine equipment export specialist providing high-performance Oily Water Separators (OWS) tailored for new shipbuilding and ship-repair projects. Our solutions comply with MARPOL Annex I, IMO MEPC.107(49), and DNV/GL standards, ensuring seamless integration into vessels of all sizes while maintaining strict environmental regulations. We deliver engineered-for-purpose OWS systems with rigorous quality control, global export readiness, and end-to-end technical support.

Technical Specifications

Our OWS units are precision-engineered for marine environments, with customizable configurations to meet vessel-specific requirements.

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Material | Aluminum alloy (A5052-H32) / Marine-grade steel (ASTM A36, Grade A) | ISO 12944-2 (C5-M corrosion class) |

| Watertightness | IP66 rated, Class A weathertight construction (SOLAS II-1/12) | SOLAS Chapter II-1, Regulation 12 |

| Flow Rate | 0.5–50 m³/h (customizable per vessel design) | IMO MEPC.107(49) |

| Discharge Oil Content | ≤15 ppm (verified by certified oil content monitoring system) | MARPOL Annex I, Regulation 14 |

| Installation | Modular bolted/flanged connections; compatible with existing piping systems | DNV GL Type Approval Certificate |

| Operating Pressure | 0.5–1.0 MPa (standard); up to 1.6 MPa (custom) | ABS/LR classification standards |

Key Compliance Standards

Our OWS systems undergo rigorous testing to meet the strictest global regulations:

MARPOL Annex I, Regulation 14: Mandatory for vessels ≥400 GRT; ensures oil content in discharged water ≤15 ppm.

IMO MEPC.107(49): Revised performance criteria for OWS, including real-time monitoring, alarms, and automatic shutdown systems.

DNV GL Type Approval: Validated structural integrity, operational reliability, and safety under extreme marine conditions.

SOLAS Chapter II-1: Watertight/weathertight integrity for hull penetrations and compartmentalization.

ISO 9001 Certified Manufacturing: End-to-end quality control from raw material sourcing to final testing.

Installation & Support Services

We provide comprehensive support for new-build projects and retrofit installations:

New Shipbuilding: Pre-integration design support, CAD drawings, and coordination with shipyard teams for seamless OWS integration during construction.

Ship Repair & Refit: Modular retrofit kits with minimal downtime; on-site engineering teams for rapid installation and commissioning.

Technical Documentation: Full compliance certificates, operation manuals, and maintenance guides in English/Chinese.

Global After-Sales: 24/7 technical assistance, spare parts logistics, and remote diagnostics for continuous operational reliability.

Why Partner with Hangzhou Star Marine Technology?

Proven Expertise: 10+ years supplying OWS systems to leading shipyards (e.g., COSCO, Jiangnan Shipyard) and owners globally.

Custom Engineering: Tailored dimensions, flow rates, and material specifications for unique vessel requirements.

Quality Assurance: 100% pre-shipment testing (pressure, watertightness, oil separation efficiency).

Export-Ready Packaging: ISO-standard crate design for safe global shipping; customs clearance support.

Contact Our Expert Team

For tailored OWS solutions that meet your vessel’s regulatory and operational needs, contact our dedicated Product Manager today.

Product Manager: Kacher YE

📞 Tel/WhatsApp: +86-178-16869405

📧 Email: [email protected]

Hangzhou Star Marine Technology Co., Ltd. – Your trusted partner for compliant, high-performance marine equipment worldwide.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160