Stainless Steel Marine Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Stainless Steel Marine Valve

Marine Industry Demand for Stainless Steel Marine Valves

Stainless steel marine valves are critical components in the safe and efficient operation of modern vessels across commercial shipping, offshore platforms, and naval fleets. These valves serve essential functions in controlling the flow of seawater, ballast, fuel, lubricants, and other vital fluids within a ship’s piping systems. Their performance directly impacts vessel integrity, operational reliability, and crew safety. Given the harsh marine environment—characterized by high salinity, fluctuating pressures, and continuous vibration—valve materials must exhibit exceptional corrosion resistance, mechanical strength, and long-term durability. Stainless steel, particularly grades such as 316 and duplex 2205, meets these demands due to its superior resistance to pitting, crevice corrosion, and stress cracking in chloride-rich conditions.

The failure of a marine valve can lead to catastrophic outcomes, including flooding, loss of propulsion, or environmental contamination. For this reason, classification societies such as DNV, ABS, LR, and CCS enforce strict standards on valve design, material certification, and performance testing. Valves must undergo rigorous pressure testing, non-destructive examination (NDE), and material traceability verification to ensure compliance. Stainless steel marine valves are often specified in critical zones such as engine room cooling systems, firefighting networks, ballast control systems, and bilge management, where reliability under emergency conditions is non-negotiable.

In recent years, global shipbuilders and marine equipment suppliers have increasingly prioritized cost-effective sourcing without compromising quality. Hangzhou Star Marine Technology Co., Ltd. has emerged as a trusted manufacturer and exporter of high-performance stainless steel marine valves, offering a compelling value proposition for international buyers. Based in China, Star Marine leverages advanced manufacturing capabilities, including CNC machining, automated welding, and in-house testing facilities, to deliver valves that meet or exceed international standards. By integrating lean production processes and maintaining direct control over raw material sourcing, the company achieves significant cost efficiencies that are passed on to clients.

Moreover, Star Marine provides full certification packages, including Material Test Reports (MTRs), Factory Acceptance Tests (FAT), and third-party inspection coordination, ensuring seamless compliance with global regulatory frameworks. The company’s export experience spans major maritime markets including Southeast Asia, the Middle East, Europe, and South America, supported by reliable logistics and after-sales technical support.

The following table outlines key advantages of sourcing stainless steel marine valves from Star Marine China:

| Feature | Benefit |

|---|---|

| Material Compliance | ASTM A351 CF8M (SS316), CF3M, and duplex 2205 available |

| Certification | DNV-GL, CCS, ABS, LR, BV, and ISO 9001 certified manufacturing |

| Pressure Testing | 1.5x working pressure hydrostatic test, pneumatic shell test |

| Traceability | Full heat number traceability and MTRs for all components |

| Cost Efficiency | 15–30% cost advantage over EU and North American suppliers |

| Lead Time | Average 4–6 weeks for standard valve orders |

| Export Packaging | Seaworthy, anti-corrosion packaging with clear labeling |

By combining technical excellence with competitive pricing and reliable delivery, Hangzhou Star Marine Technology supports shipyards and operators in enhancing safety and reducing total lifecycle costs.

Technical Specs & Approval

Technical Specifications: Stainless Steel Marine Valves

Hangzhou Star Marine Technology Co. Ltd. designs and manufactures stainless steel marine valves to stringent international maritime standards, ensuring reliability in corrosive seawater environments, high-pressure systems, and critical vessel operations. These valves are engineered for applications including ballast control, fuel transfer, cooling systems, and firefighting networks. Material selection, pressure integrity, and compliance with global classification society requirements form the foundation of our technical framework. While 316L stainless steel constitutes the primary material for superior corrosion resistance and weldability, we also offer bronze and cast steel variants for specialized operational demands, such as bronze for seawater service or cast steel for high-temperature fuel systems. All valves undergo rigorous hydrostatic and pneumatic testing per ISO 5208 leakage rates, with pressure ratings spanning PN6 (6 bar) to PN40 (40 bar), accommodating low-pressure ventilation to high-pressure hydraulic circuits.

The following table details core technical parameters for our standard stainless steel marine valve series:

| Parameter | Value Range | Standard Reference |

|---|---|---|

| Nominal Diameter (DN) | DN15 to DN600 | ISO 6708 |

| Pressure Class | PN6, PN10, PN16, PN25, PN40 | EN 1092-1 / ISO 7005-1 |

| Temperature Range | -40°C to +200°C | ASME B16.34 |

| Body Material | ASTM A351 CF8M (316L SS) | ASTM A743/A744 |

| Trim Material | 316 SS, Monel, or Stellite | NACE MR0175 |

| Seat Seal | PTFE, RPTFE, or Metal-to-Metal | ISO 5752 |

| Face-to-Face Length | ISO 5752 Series 1 & 2 | ISO 5752 |

| Testing | Shell: 1.5x PN; Seat: 1.1x PN | API 598 / ISO 5208 Cat. A |

| End Connection | Flanged, Threaded, Welding Ends | ASME B16.5, B16.11, EN 1092-1 |

Valve bodies undergo 100% hydrostatic shell testing at 1.5 times the nominal pressure rating, with seat leakage rates strictly adhering to ISO 5208 Category A (metal seats) or Category IV (soft seats). Flange dimensions comply with DIN 2501, JIS B2220, or ASME B16.5 standards to ensure seamless integration with global piping systems. For valves destined for hazardous zones (e.g., fuel oil lines), we implement additional fire-safe testing per API 607/API 6FA, utilizing resilient graphite seals that maintain integrity during fire exposure. Surface finishes achieve Ra ≤ 0.8 µm on sealing surfaces to minimize friction and erosion in abrasive media. All products carry traceable material certifications (EN 10204 3.1) and are validated by ABS, DNV, LR, CCS, or KR surveyors prior to shipment.

Hangzhou Star prioritizes operational safety through precise dimensional tolerances and non-destructive examination (NDE) of critical welds via MPI or DPT. Our PN40-rated valves, for instance, feature reinforced body necks and extended bonnet designs to manage thermal stress in steam applications. Export documentation includes comprehensive material test reports (MTRs), pressure test records, and 3D CAD models for pre-installation verification. This technical rigor ensures compliance with SOLAS Chapter II-1 regulations and classification society rules, providing vessel operators with valves that deliver leak-tight performance across 10,000+ operational cycles under dynamic marine conditions.

Shipbuilding Solutions

Comprehensive Stainless Steel Marine Valve Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered excellence in stainless steel marine valves, supporting shipbuilders and repair yards with reliable, compliant, and high-performance solutions. Our valves are designed to meet the rigorous demands of marine environments, offering superior corrosion resistance, durability, and operational efficiency. Whether for new vessel construction or in-service repairs, Star Marine ensures seamless integration, timely delivery, and full technical support.

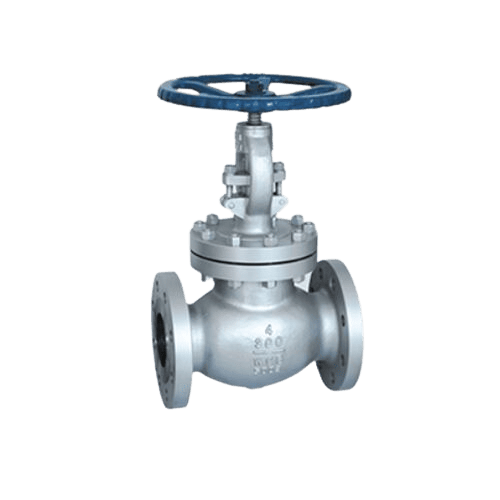

For new shipbuilding projects, we collaborate closely with design teams to supply valves that comply with international standards including ISO 10434, API 6D, and DNV, ABS, LR, and CCS type approvals. Our product range includes stainless steel gate, globe, check, ball, and butterfly valves, all manufactured using high-grade SS316 and duplex stainless steel to resist saltwater corrosion and maintain long-term integrity. Each valve undergoes stringent pressure testing, material verification, and non-destructive examination to ensure reliability under extreme conditions.

In repair and retrofit applications, Star Marine provides rapid-response valve solutions to minimize vessel downtime. Our global logistics network enables delivery within 7–15 days for standard models, with expedited manufacturing available for critical spares. Our technical team supports retrofit compatibility assessments, ensuring dimensional and performance alignment with existing systems. With a stockholding strategy across key maritime hubs, we maintain readiness for emergency repair demands in major shipyards and ports.

Our commitment to quality is reinforced through ISO 9001:2015 certification and full traceability from raw material sourcing to final inspection. All valves are supplied with Material Test Certificates (MTCs), Pressure Test Reports, and Declaration of Conformity to support classification society audits and regulatory compliance.

Product Specifications – Stainless Steel Marine Valves

| Parameter | Specification |

|---|---|

| Body Material | ASTM A351 CF8M (SS316), CD3MN (Duplex) |

| Trim Material | SS316, 17-4PH, or Stellite for enhanced wear resistance |

| Pressure Class | ANSI 150 to 600, PN16 to PN100 |

| Size Range | DN15 to DN600 (1/2″ to 24″) |

| End Connections | Flanged (RF, RTJ), Butt-welded, Socket-welded |

| Temperature Range | -20°C to +200°C (standard); cryogenic and high-temp options available |

| Testing Standards | API 598, ISO 5208 (Shell and Seat Leakage) |

| Certifications | DNV-GL, ABS, LR, BV, CCS, KR, RINA, IRS |

| Actuation Options | Manual, Gear Operated, Pneumatic, Electric |

Star Marine’s technical export team provides 24-hour response support for project inquiries, technical drawings, and spare parts requests. We offer OEM/ODM services tailored to specific vessel requirements and support multilingual documentation for global operations. Our goal is to be a trusted partner in marine valve supply—ensuring safety, compliance, and operational continuity across the shipbuilding and repair lifecycle.

Packaging & Logistics

Packaging & Logistics Protocol for Stainless Steel Marine Valves

Hangzhou Star Marine Technology implements rigorously standardized packaging and logistics procedures for all stainless steel marine valves to ensure integrity during global transit. Our methodology adheres strictly to IMO, ISO, and IATA regulations, with particular emphasis on preventing corrosion, physical impact damage, and moisture ingress. All export shipments originate from our certified facilities in Hangzhou, with final consolidation and dispatch executed through the deep-water ports of Ningbo-Zhoushan and Shanghai, leveraging their strategic connectivity to major global shipping lanes and specialized breakbulk handling capabilities for heavy industrial cargo.

Primary containment utilizes custom-engineered wooden export cases constructed from ISPM 15-compliant softwood. Each case undergoes mandatory kiln-drying to a moisture content below 20% prior to fabrication, followed by heat treatment at a minimum core temperature of 56°C for 30 minutes. The ISPM 15 certification mark, including the country code (CN), producer code, and HT designation, is permanently branded on two exterior faces of every case. Internal valve surfaces receive a dual-layer corrosion protection treatment: first, a solvent-based volatile corrosion inhibitor (VCI) applied to all wetted parts, followed by hermetic sealing within multi-ply polyethylene vapor barrier bags filled with desiccant packs (minimum 50g per m³). Cases are internally lined with closed-cell polyethylene foam (25mm thickness) to absorb shock and prevent component movement.

For valves exceeding 50kg or with complex geometries (e.g., triple-offset butterfly valves), secondary reinforcement is provided via galvanized steel pallets. These pallets conform to EUR-pallet specifications (1200 x 800mm) with a dynamic load capacity of 1500kg. Valves are secured to pallets using stainless steel strapping (minimum 19mm width) tensioned to 250daN, with corner protectors preventing strap-induced deformation. All wooden components are free of bark, sawdust residue, and internal voids exceeding 3mm. External case surfaces are treated with a water-repellent coating to mitigate condensation risks during ocean transit.

The following table details critical packaging specifications:

| Component | Specification | Compliance Standard |

|---|---|---|

| Primary Case | Kiln-dried pine, 18mm planks, double-wall corners | ISPM 15 HT 56°C/30min |

| Internal Lining | 25mm polyethylene foam + VCI-treated polyethylene | ASTM D3951 Type II |

| Desiccant | Silica gel, 50g/m³ minimum, humidity indicator | MIL-D-3464E |

| Steel Pallet | Galvanized steel, 1200x800mm, 1500kg dynamic load | EUR-pallet standard |

| Strapping | 19mm stainless steel, tensioned to 250daN | ISO 15402 |

| External Treatment | Water-repellent acrylic coating | IMO MSC/Circ.1120 Annex 2 |

Shipments are consolidated at Ningbo-Zhoushan Port (CN NGB) or Shanghai Port (CN SHA) based on vessel schedules and destination routing efficiency. We utilize dedicated container freight stations (CFS) with climate-controlled staging areas for final verification. All documentation—including phytosanitary certificates referencing ISPM 15 treatment, packing lists with case serial numbers, and material test reports—accompanies the cargo electronically via EDI and physically within a waterproof pouch affixed to the lead case. This integrated approach ensures valves arrive at global shipyards and repair facilities in as-manufactured condition, fully compliant with the stringent demands of marine operations.

Contact Star Marine

Contact Star Marine – Your Trusted Partner for Stainless Steel Marine Valves

At Hangzhou Star Marine Technology Co., Ltd., we specialize in the design, manufacturing, and global export of high-performance stainless steel marine valves engineered to meet the rigorous demands of the maritime industry. Our valves are built to comply with international marine standards, including ISO, DNV, ABS, CCS, and BV certifications, ensuring reliability, corrosion resistance, and long-term operational integrity in harsh marine environments. Whether you are equipping a new vessel or upgrading existing systems, our products are designed to deliver optimal performance in seawater, fuel, ballast, and bilge systems.

We understand that selecting the right valve solution involves technical precision, regulatory compliance, and supply chain reliability. That’s why our team of marine engineers and export specialists is committed to providing personalized support from initial inquiry through final delivery. Our product range includes stainless steel ball valves, gate valves, globe valves, check valves, and butterfly valves, all manufactured using high-grade AISI 316/L and 304/L stainless steel with advanced sealing technologies to prevent leakage and ensure tight shut-off performance.

To assist you in selecting the right valve configuration for your application, we offer detailed technical documentation, 3D CAD models, material traceability reports, and factory test certifications (including shell and seat pressure testing). Our valves are pressure-rated up to 1000 psi (70 bar) depending on size and design, with temperature tolerance ranging from -20°C to +200°C, making them suitable for a wide range of onboard systems.

For project-specific inquiries, bulk orders, or technical consultations, we invite you to contact our dedicated Product Manager for marine valves, Kacher YE. With over 12 years of experience in marine equipment export and valve system integration, Kacher provides expert guidance on product selection, customization options, and compliance requirements for global shipping fleets.

Below is a summary of our standard stainless steel marine valve specifications:

| Parameter | Specification |

|---|---|

| Material | AISI 316/L, AISI 304/L |

| Size Range (DN) | DN10 – DN300 |

| Pressure Rating | PN16, PN25, Class 150, Class 300 |

| Temperature Range | -20°C to +200°C |

| End Connections | Threaded, Socket Weld, Flanged (PN, ANSI, JIS) |

| Certifications | DNV-GL, ABS, CCS, BV, LR, RINA, ISO 9001:2015 |

| Testing Standards | API 598, ISO 5208 |

| Supply Type | OEM, ODM, Private Label Available |

To discuss your valve requirements, request a quote, or schedule a technical review, please reach out directly to Kacher YE via email at [email protected]. We respond to all inquiries within 4 business hours and support communication in English, Mandarin, and Spanish. Let Hangzhou Star Marine Technology be your strategic partner in delivering safe, durable, and compliant valve solutions for the global marine industry.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160