Stainless Steel Windlass – Marine Solution Guide 2025

Content Navigation

Marine Insight: Stainless Steel Windlass

Marine Industry Demand for Stainless Steel Windlass

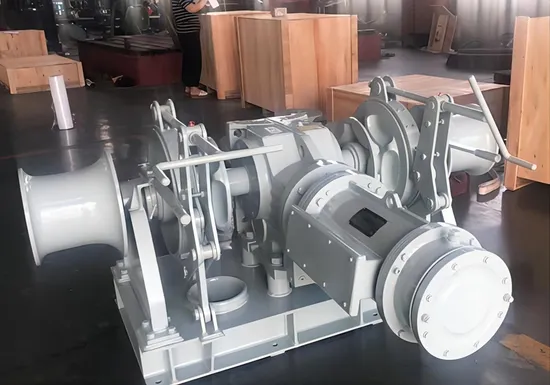

In the maritime industry, the reliability and performance of deck machinery directly influence vessel safety, operational efficiency, and crew confidence during anchoring operations. Among these critical systems, the stainless steel windlass plays a pivotal role in ensuring secure anchoring under diverse sea conditions. As vessels navigate through coastal zones, harbors, and offshore areas, the ability to deploy and retrieve anchors swiftly and safely is essential. A high-quality stainless steel windlass not only withstands the harsh marine environment but also reduces maintenance downtime and enhances long-term durability.

Stainless steel windlasses are increasingly preferred across commercial fishing vessels, offshore support vessels, yachts, and small cargo carriers due to their superior corrosion resistance and mechanical strength. Unlike conventional carbon steel windlasses that require extensive protective coatings and frequent maintenance, stainless steel variants—particularly those fabricated from marine-grade alloys such as AISI 316—offer inherent resistance to saltwater corrosion. This characteristic is crucial in extending service life and minimizing unexpected failures during critical anchoring maneuvers.

Moreover, the integration of a robust stainless steel windlass contributes to overall vessel safety by ensuring reliable holding power and smooth operation under load. Failures in anchoring systems can lead to drifting, collisions, or grounding, especially in adverse weather. A well-engineered windlass provides consistent performance in high-tension scenarios, supports safe crew operation through ergonomic design, and integrates seamlessly with chain stoppers, wildcats, and deck piping systems.

From an operational cost perspective, sourcing stainless steel windlasses from Hangzhou Star Marine Technology Co., Ltd. presents a strategic advantage for global buyers. Based in China, our facility leverages advanced manufacturing capabilities, strict quality control protocols, and direct supply chain management to deliver premium deck machinery at competitive export pricing. By combining precision engineering with cost-efficient production, Star Marine offers products that meet international standards—including ISO 9001 and DNV-GL type approvals—without the premium price tags associated with European or North American manufacturers.

The following table outlines key comparative advantages of sourcing stainless steel windlasses from Star Marine:

| Feature | Star Marine Stainless Steel Windlass | Typical Market Alternatives |

|---|---|---|

| Material Grade | AISI 316/L Marine-Grade Stainless Steel | AISI 304 or Coated Carbon Steel |

| Corrosion Resistance | Excellent, suitable for tropical and arctic zones | Moderate to poor, requires frequent maintenance |

| Load Capacity Range | 500 kg to 10,000 kg | 500 kg to 8,000 kg |

| Certification Compliance | ISO 9001, DNV-GL, CCS | Varies, often limited regional certification |

| Lead Time (Export) | 4–6 weeks | 8–12 weeks |

| FOB Price Competitiveness | Up to 20% lower than EU/US equivalents | Higher due to labor and overhead costs |

By choosing Hangzhou Star Marine Technology, clients gain access to technically advanced, safety-focused windlass systems that support long-term vessel integrity while optimizing procurement budgets.

Technical Specs & Approval

Technical Specifications: Stainless Steel Windlass Systems

Hangzhou Star Marine Technology Co. Ltd. manufactures premium stainless steel windlasses engineered for demanding marine environments. Our deck machinery solutions prioritize corrosion resistance, operational reliability, and compliance with international maritime standards. The following technical specifications detail critical performance parameters for our standard product range, designed to accommodate vessels from 15m to 200m LOA. All units undergo rigorous salt spray testing per ASTM B117 and are certified to ISO 15085 and DNV-ST-N001 standards. Material composition utilizes ASTM A182 F316L forged stainless steel for critical load-bearing components, ensuring superior tensile strength and pitting resistance in saline conditions.

| Parameter | Specification Range | Notes |

|---|---|---|

| Model Range | HS-125 to HS-600 | Denotes chain size compatibility |

| Pull Load (kN) | 25 kN to 500 kN | Static pull capacity at gypsy wheel |

| Chain Diameter (mm) | 12.5 mm to 60 mm | ISO 1704 / DIN 766 compliant |

| Drive System | Electric or Hydraulic | Customizable per vessel requirements |

| Electric Motor Power | 1.5 kW to 22 kW | 24V DC / 110-440V AC options |

| Hydraulic Motor Torque | 500 Nm to 8,500 Nm | 180-350 bar operating pressure |

| Gypsy Wheel Type | Single or Dual | Interchangeable for stud link chains |

| Brake Holding Capacity | 1.5x Working Load Limit (WLL) | Fail-safe mechanical brake standard |

| IP Rating | IP56 (Housing) / IP67 (Motor) | Conforms to IEC 60529 |

| Certifications | DNV-GL, LR, ABS, CCS, RINA | Full Type Approval documentation |

Pull load capacity is meticulously calibrated to exceed ISO 3911 minimum requirements, with each model rated for continuous duty cycles at 30% of maximum pull load. Chain diameter compatibility spans 12.5mm (1/2″) to 60mm (2-3/8″), covering all common stud link chain grades (G3, G4, G7). The windlass gypsy wheels feature precision-machined pockets with self-cleaning geometry to prevent chain jamming during retrieval or deployment.

Our dual-drive architecture provides optimal flexibility for global vessel integration. Electric drive systems utilize brushless DC motors with integrated thermal overload protection, ideal for yachts and commercial vessels up to 80m. Hydraulic variants employ radial piston motors with pressure-compensated flow control, delivering consistent torque for offshore support vessels and tankers requiring high-cycle durability. All drive interfaces comply with IEC 60092 marine electrical standards, with hydraulic manifolds meeting ISO 4413 pressure testing protocols.

Material integrity is non-negotiable in our manufacturing process. Stainless steel components undergo dual-pass TIG welding with 316L filler metal, followed by post-weld passivation per ASTM A967. Non-destructive testing (NDT) via dye penetrant inspection validates all critical welds. The brake system incorporates sintered metal friction plates rated for 50,000+ engagement cycles without maintenance. For export compliance, every unit ships with traceable material test reports (MTRs), 3.2 EN 10204 certificates, and multilingual operation manuals meeting SOLAS Chapter V requirements. Custom configurations for chain locker dimensions, control panel integration, and remote operation are available upon technical consultation.

Shipbuilding Solutions

Stainless Steel Windlass Solutions for Shipbuilding and Repair – Hangzhou Star Marine Technology Co., Ltd.

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive deck machinery solutions tailored to the evolving demands of shipbuilding and vessel repair. As a trusted provider of high-performance marine equipment, we specialize in stainless steel windlasses engineered for durability, corrosion resistance, and reliable anchoring operations in harsh maritime environments. Our integrated approach ensures seamless integration into both new vessel construction and retrofit projects, supporting shipyards and shipowners with technical precision and rapid response.

Our stainless steel windlasses are designed in accordance with international marine standards, including ISO 3911, DNV, CCS, and ABS certifications. Constructed from high-grade 316L stainless steel, these units offer superior resistance to saltwater corrosion, reducing maintenance cycles and extending service life. Whether for commercial vessels, offshore support vessels, or luxury yachts, our windlasses provide robust performance with minimal operational downtime.

For new shipbuilding projects, Hangzhou Star Marine collaborates closely with naval architects and shipyards from the design phase through commissioning. We provide full technical documentation, 3D modeling support, and load calculation reports to ensure compatibility with deck layout, anchor handling requirements, and power systems. Our engineering team supports customization in gypsy configuration, chain size, pulling capacity, and drive type—ensuring optimal performance for each vessel profile.

In ship repair and retrofit scenarios, we offer fast-turnaround solutions with global spare parts availability and on-site technical assistance. Our windlasses are designed for modular serviceability, enabling quick replacement of critical components such as motors, brakes, and chainwheel segments without full dismantling. This design philosophy minimizes dry dock time and reduces repair costs—critical factors in commercial vessel operations.

To support rapid project execution, Hangzhou Star Marine maintains an agile supply chain with strategic stockpiling of standard models and key components. Our export department ensures prompt documentation processing, compliance with destination country regulations, and coordination with freight partners for reliable delivery timelines.

Below is an overview of standard technical specifications for our flagship stainless steel windlass series:

| Specification | Details |

|---|---|

| Material | 316L Stainless Steel (AISI) |

| Capacity Range | 500 kg – 15,000 kg (holding load) |

| Chain Size Compatibility | 14 mm – 42 mm (ISO R613) |

| Drive Type | Electric, Electro-Hydraulic, or Manual |

| Certification | DNV-GL, ABS, CCS, BV, LR |

| Brake Type | Band brake with safety interlock |

| Operating Environment | -25°C to +55°C, IP56 minimum protection |

| Customization | Gypsy profile, remote control, emergency operation |

Hangzhou Star Marine Technology Co., Ltd. is committed to delivering integrated, reliable, and export-ready deck machinery solutions. With a focus on engineering excellence and customer support, we serve as a strategic partner in global shipbuilding and marine repair operations.

Packaging & Logistics

Packaging & Logistics for Stainless Steel Windlass Exports

Hangzhou Star Marine Technology implements rigorous packaging protocols for all stainless steel windlass exports to ensure equipment integrity during global maritime transit. As critical deck machinery operating in highly corrosive saltwater environments, windlasses require specialized protection against physical damage, moisture ingress, and contamination throughout the supply chain. Our standard methodology adheres strictly to International Maritime Organization (IMO) guidelines and destination country import regulations, particularly concerning wood packaging materials.

All wooden export crates utilized for windlass shipments comply fully with ISPM 15 (International Standards for Phytosanitary Measures No. 15). This mandatory certification ensures wood has undergone approved heat treatment to eliminate pest risks, featuring the internationally recognized IPPC mark stamped visibly on each crate component. Crates are constructed from robust, kiln-dried hardwood or plywood, engineered to withstand stacking pressures within ocean containers and resist deformation during handling. Internal protection includes custom-fitted polyethylene foam inserts securing the windlass base and gypsy wheel, supplemented by vapor corrosion inhibitor (VCI) paper wrapping and desiccant packs to maintain a moisture-free microclimate. Steel pallets, fabricated from galvanized structural steel with a minimum load capacity of 3,000 kg, serve as the foundation for consolidated shipments or single-unit air freight. Units are firmly anchored to the pallet using marine-grade stainless steel strapping, with all moving parts immobilized and electrical components sealed in anti-static, waterproof barrier bags. Critical surfaces receive an additional temporary corrosion-inhibiting coating approved for marine equipment.

Shipments originate exclusively from China’s premier deep-water ports, Ningbo-Zhoushan and Shanghai, leveraging their extensive global container services and efficient customs clearance infrastructure. Our Ningbo and Shanghai-based logistics partners manage all pre-shipment documentation, including the ISPM 15 certificate, commercial invoice, packing list, and certificate of origin, ensuring seamless customs processing at destination ports. Container loading occurs under direct supervision by Hangzhou Star quality assurance personnel to verify correct securing and environmental protection measures. We utilize 20-foot and 40-foot dry freight containers, with careful stowage planning to prevent shifting and maximize space utilization while maintaining safe clearance distances.

The following table details our standard packaging configurations:

| Packaging Type | Primary Material | Typical Dimensions (LxWxH) | Key Protective Features | Primary Use Case |

|---|---|---|---|---|

| ISPM 15 Wooden Crate | Heat-treated hardwood/plywood | 1800x1200x1500 mm (Customizable) | VCI paper wrapping, desiccant packs, custom foam inserts, moisture barrier film | Full container loads (FCL), multiple units, high-value shipments |

| Steel Pallet System | Galvanized structural steel | 1200x1000x200 mm (Pallet base) | Marine-grade strapping, anti-static barrier bags, temporary corrosion coating | Less than container load (LCL), air freight, single-unit shipments |

Hangzhou Star maintains continuous oversight from factory dispatch through vessel loading. Real-time shipment tracking is provided to clients, and all packaging materials undergo final inspection against our internal AS9100-inspired quality management system prior to container sealing. This systematic approach guarantees that your stainless steel windlass arrives at its destination port in operational condition, ready for immediate installation, thereby safeguarding your operational timelines and investment.

Contact Star Marine

For marine equipment buyers, shipbuilders, and OEM partners seeking high-performance deck machinery, Hangzhou Star Marine Technology Co., Ltd. stands at the forefront of innovation and reliability in the maritime industry. Our stainless steel windlasses are engineered to meet the rigorous demands of commercial and high-end recreational vessels, combining corrosion resistance, mechanical strength, and long service life in harsh marine environments. As a trusted manufacturer specializing in deck machinery, we are committed to delivering solutions that ensure operational safety, efficiency, and compliance with international maritime standards.

If you are evaluating premium-grade stainless steel windlasses for new vessel construction, retrofit projects, or fleet procurement, we invite you to contact our Product Manager, Kacher YE, directly. With extensive technical expertise in marine anchoring systems and export logistics, Kacher serves as the primary liaison for international clients, providing detailed product specifications, technical support, and tailored quotations based on project requirements. Whether your needs involve horizontal or vertical windlass configurations, customized pulling capacity, or integration with chain stoppers and hawse pipes, our engineering team supports full customization in alignment with classification society rules including CCS, ABS, DNV, LR, and BV.

We understand that selecting the right windlass involves more than performance data—it requires confidence in supply chain reliability, after-sales service, and engineering collaboration. At Star Marine, we offer comprehensive export documentation, factory acceptance testing (FAT), and global shipping coordination to ensure seamless delivery to shipyards and distributors worldwide. Our production facility in Hangzhou is equipped with CNC machining centers, automated welding systems, and material testing laboratories to maintain consistent quality across all stainless steel components, including drums, chainwheels, and gear housings.

To initiate a technical discussion or request a formal quotation, please reach out to Kacher YE via email at [email protected]. We respond to all inquiries within 12 business hours and can provide CAD drawings, installation manuals, and product certifications upon request.

Below is an overview of our standard stainless steel windlass specifications for reference:

| Parameter | Specification |

|---|---|

| Material | AISI 316 Stainless Steel (Main Components) |

| Working Load (SWL) | Up to 25 tons |

| Chain Size Compatibility | 8mm to 22mm (ISO 1704:2012) |

| Drive Type | Electric, Hydraulic, or Electro-Hydraulic |

| Classification | ABS, CCS, DNV-GL, LR, RINA (Available on Request) |

| Certifications | ISO 9001:2015, CE, IACS |

| Warranty | 18 months from date of shipment |

Partner with Hangzhou Star Marine Technology for windlass solutions built to endure saltwater exposure, mechanical stress, and continuous duty cycles. Contact Kacher YE today to discuss your project requirements and discover how our stainless steel windlasses can enhance the safety and reliability of your marine operations.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160