High Holding Power Anchor – Marine Solution Guide 2025

Content Navigation

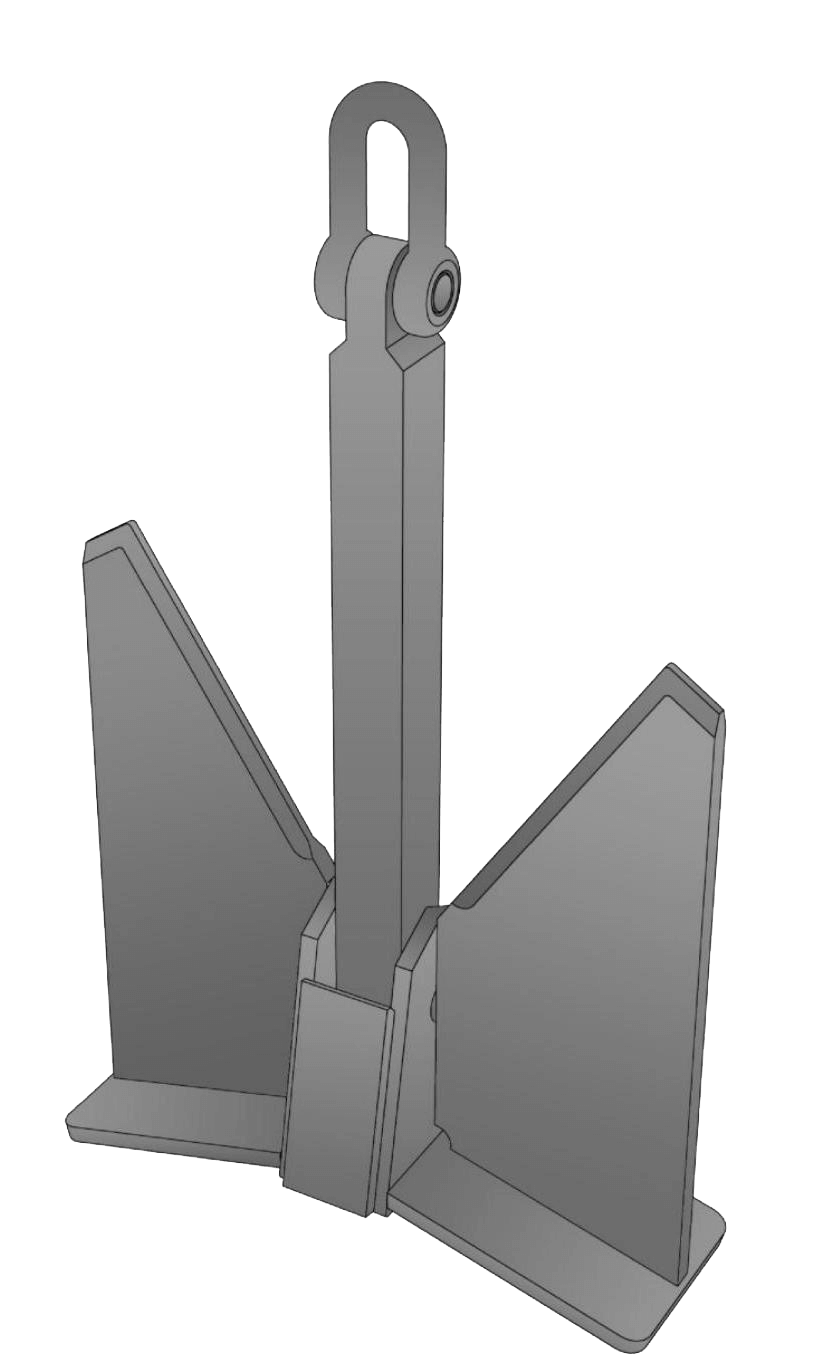

Marine Insight: High Holding Power Anchor

Marine Industry Demand for High Holding Power Anchors

In the maritime industry, vessel safety and operational reliability are paramount, particularly in challenging sea conditions and adverse weather. A critical component in ensuring vessel stability and security is the anchoring system, with the high holding power anchor playing a central role. These anchors are specifically engineered to provide superior grip on seabeds across diverse geologies, including sand, mud, clay, and rocky substrates. Their enhanced holding capacity significantly reduces the risk of dragging, which can lead to collisions, groundings, or loss of cargo and crew safety. As global shipping traffic increases and vessels grow in size and complexity, the demand for high performance anchoring solutions has intensified.

High holding power anchors, such as the AC-14, AC-16, and Hall types, are designed with large fluke areas, optimized weight distribution, and streamlined shank geometry to maximize seabed penetration and resistance to pull-out forces. These features are essential for large commercial vessels, offshore support units, and naval fleets operating in deep waters or dynamic environments. Regulatory bodies such as the International Maritime Organization (IMO) and classification societies including ABS, DNV, and CCS emphasize compliance with anchoring performance standards, further driving the adoption of high holding power designs.

Hangzhou Star Marine Technology Co., Ltd. has established itself as a trusted manufacturer and exporter of high-quality marine anchoring equipment. Our high holding power anchors are fabricated using premium-grade marine steel, heat-treated for durability and resistance to corrosion and impact. Each anchor undergoes rigorous quality control, including non-destructive testing (NDT), load testing, and dimensional verification, ensuring full compliance with international standards such as ISO 18174 and CCS certification protocols.

Sourcing high holding power anchors from Star Marine China offers significant cost advantages without compromising on quality. Our integrated manufacturing capabilities, efficient supply chain, and strategic location in Hangzhou enable competitive pricing and reliable delivery timelines. Additionally, we offer customization options to meet specific vessel requirements, including weight adjustments, shank configurations, and surface coatings for extended service life in corrosive environments.

The following table outlines key specifications and performance metrics of our standard high holding power anchor models:

| Model | Weight Range (kg) | Holding Power (kN) | Compliance Standards | Typical Vessel Application |

|---|---|---|---|---|

| AC-14 | 500 – 15,000 | 1,200 – 45,000 | ISO 18174, CCS, ABS | Container Ships, Tankers |

| AC-16 | 700 – 20,000 | 1,800 – 60,000 | DNV-GL, LR, NK | Bulk Carriers, Offshore Vessels |

| Hall Type | 300 – 10,000 | 900 – 30,000 | BV, RINA, CCS | Tugs, Supply Vessels |

By combining technical excellence, international certifications, and cost-effective manufacturing, Hangzhou Star Marine Technology provides maritime operators with a strategic advantage in vessel safety and operational efficiency.

Technical Specs & Approval

Hangzhou Star Marine Technology Co., Ltd. – High Holding Power Anchor Technical Specifications

Hangzhou Star Marine Technology Co., Ltd. designs and manufactures High Holding Power (HHP) anchors to stringent international maritime standards, ensuring optimal seabed penetration, resistance to dragging, and long-term reliability across diverse operational environments. Our HHP anchors, compliant with ISO 15792:2018 for shipboard anchor equipment, represent a significant advancement over traditional stockless designs, offering superior holding characteristics essential for vessel safety in demanding conditions. The technical parameters detailed below reflect our commitment to engineering excellence and adherence to classification society requirements, including DNV, LR, ABS, and CCS. Precise specification selection is critical and must align with vessel size, operational profile, and anticipated seabed composition.

Material Grade Certification

All Hangzhou Star HHP anchors are manufactured from high-tensile steel meeting rigorous marine-grade specifications. The U2 grade utilizes steel conforming to ISO 4990:2015 Grade B or equivalent, suitable for general commercial vessel applications where ultimate strength requirements are defined by standard classification rules. The U3 grade employs ultra-high-strength steel per ISO 4990:2015 Grade D or superior equivalents, specifically engineered for vessels operating in extreme environments, ice-infested waters, or where enhanced structural integrity under maximum load is paramount. Both grades undergo full material traceability and comprehensive mechanical testing, including tensile strength, yield point, elongation, and impact toughness verification at sub-zero temperatures as required.

Weight and Holding Power Performance

Anchor weight is precisely calculated based on the vessel’s displacement and windage area, following standard classification society rules. Hangzhou Star HHP anchors deliver exceptional holding power relative to their mass. The U2 grade achieves a minimum holding power to weight ratio of 50:1 in medium-density sandy seabeds under controlled ISO 15792 testing conditions. The U3 grade exceeds this benchmark, consistently demonstrating ratios of 60:1 or higher in identical test scenarios, attributable to its optimized fluke geometry, shank profile, and increased structural robustness. This superior performance translates directly to reduced anchor weight requirements for equivalent holding capacity compared to conventional designs, offering potential vessel weight savings.

Surface Treatment and Corrosion Protection

To ensure longevity in aggressive marine environments, all Hangzhou Star HHP anchors receive a comprehensive corrosion protection system. The primary treatment is hot-dip galvanizing per ISO 1461, providing a minimum zinc coating thickness of 80µm on all critical surfaces. For vessels requiring extended service life or operation in highly corrosive waters, an optional duplex system is available, combining the hot-dip galvanized base with a topcoat of high-performance epoxy marine paint meeting ISO 12944 C5-M requirements. All surface preparation adheres strictly to Sa 2.5 (ISO 8501-1) standards prior to coating application, guaranteeing optimal adhesion and protection integrity.

The following table summarizes the key technical parameters for Hangzhou Star’s standard HHP anchor offerings:

| Parameter | U2 Specification | U3 Specification |

|---|---|---|

| Material Standard | ISO 4990:2015 Grade B / Equivalent | ISO 4990:2015 Grade D / Equivalent |

| Tensile Strength | 400 – 520 MPa | 510 – 690 MPa |

| Yield Strength | ≥ 235 MPa | ≥ 355 MPa |

| Weight Range | 500 kg – 15,000 kg | 1,000 kg – 25,000 kg |

| Min. Holding Power Ratio | 50:1 (Sandy Bottom, ISO 15792 Test) | 60:1 (Sandy Bottom, ISO 15792 Test) |

| Standard Surface Treatment | Hot-Dip Galvanized (ISO 1461, ≥80µm) | Hot-Dip Galvanized (ISO 1461, ≥80µm) |

| Optional Surface Treatment | Galvanized + Epoxy Topcoat (C5-M) | Galvanized + Epoxy Topcoat (C5-M) |

| Classification Approval | DNV, LR, ABS, CCS, etc. (Standard) | DNV, LR, ABS, CCS, etc. (U3 Category) |

Note: Holding power ratios are determined under controlled laboratory conditions per ISO 15792 Annex A using medium-density sand. Actual in-service performance varies with seabed type, scope of rode, and deployment technique. Weight ranges are indicative; specific anchor mass is determined by vessel particulars and classification society rules.

Shipbuilding Solutions

Hangzhou Star Marine Technology Co., Ltd. delivers comprehensive anchoring solutions tailored for shipbuilding and repair applications, with a focus on high holding power anchors that ensure superior seabed grip and vessel stability. As a leading marine equipment exporter, Star Marine supports shipyards and repair facilities worldwide with engineered products designed to meet international standards, including ISO 18778, DNV, ABS, and CCS certifications. Our high holding power anchors are optimized for a wide range of vessel types—from offshore support vessels and bulk carriers to yachts and naval craft—ensuring reliable performance in diverse seabed conditions.

Our anchoring systems are engineered to provide maximum holding capacity with minimal weight, reducing deck load while enhancing anchor embedment efficiency. The design incorporates advanced fluke geometry and shank profiles that promote rapid setting and resistance to dragging, even in challenging environments such as soft mud, sand, or mixed terrain. This performance is critical during new vessel construction, where safety, compliance, and operational readiness are paramount.

For ship repair projects, Star Marine offers fast-response supply chains and technical support to minimize downtime. We maintain strategic inventory levels in key Chinese ports and partner with certified foundries to ensure rapid production turnaround without compromising quality. Our team collaborates directly with shipyards and classification societies to verify compliance with project specifications, delivering documentation packages that include material test reports, NDT results, and certificate endorsements.

In addition to the anchor itself, Star Marine provides complete anchoring assemblies, including stockless or semi-stock designs, anchor chains, shackles, and windlass compatibility assessments. This integrated approach ensures seamless integration into the vessel’s mooring system and reduces coordination efforts for shipbuilders and repair managers.

Below is a comparison of standard high holding power anchor models available for export:

| Model | Weight Range (kg) | Nominal Chain Size (mm) | Holding Power (kN) | Compliance Standards |

|---|---|---|---|---|

| AC-14 (with Stock) | 500 – 5,000 | 28 – 62 | 1,200 – 12,500 | DNV-GL, ABS, LR, CCS |

| AC-14 (Stockless) | 300 – 4,800 | 26 – 60 | 1,100 – 12,000 | ISO 18778, BV, NK |

| High-Performance Delta | 400 – 6,000 | 30 – 64 | 1,500 – 14,200 | RINA, DNV, ABS |

| Custom HHP Anchors | On Request | 20 – 70 | Up to 18,000 | Project-Specific Certification |

All models are manufactured using high-tensile steel with enhanced corrosion resistance and undergo rigorous quality control, including magnetic particle inspection and load testing. Star Marine’s export team ensures compliant packaging, accurate labeling, and coordination with freight forwarders for on-time global delivery. With a dedicated technical service division, we provide pre-shipment inspections, installation guidance, and post-delivery support to ensure full customer satisfaction.

For shipbuilding and repair projects requiring reliability, speed, and compliance, Hangzhou Star Marine Technology stands as a trusted partner in high-performance anchoring solutions.

Packaging & Logistics

Packaging and Logistics Protocol for High Holding Power Anchors

Hangzhou Star Marine Technology implements rigorous packaging and logistics standards for our high holding power anchors to ensure global shipment integrity and compliance. All wooden packaging components strictly adhere to International Standards for Phytosanitary Measures No. 15 (ISPM 15). This mandatory regulation requires heat treatment or fumigation of wood exceeding 6mm thickness to mitigate the risk of invasive pest transmission across borders. Our certified wood crates feature the official ISPM 15 mark, including the country code (CN), unique producer code, and treatment abbreviation (HT for heat treatment), guaranteeing acceptance by customs authorities worldwide and preventing costly port delays or rejections. The crates are constructed from robust, kiln-dried hardwood or plywood, engineered to withstand significant compression forces during multi-modal transit and ocean container stacking.

For optimal load security and handling efficiency, anchors are systematically secured within the wooden crates using marine-grade steel strapping and custom-fitted dunnage. Critical contact points are padded with anti-corrosion VCI paper to prevent surface damage and inhibit rust formation during extended voyages. For anchors exceeding 500 kg, we utilize reinforced steel pallet bases welded to the crate structure. These pallets provide essential stability for forklift handling at origin, transshipment hubs, and destination ports, eliminating the risk of shifting or structural collapse under the anchor’s concentrated weight. The integrated steel pallet design ensures compatibility with global port infrastructure and simplifies terminal operations.

All export shipments originate exclusively through the major international hubs of Ningbo-Zhoushan Port and Shanghai Port. Ningbo-Zhoushan, consistently ranked among the world’s top three container ports, offers exceptional deep-water capabilities and streamlined customs clearance procedures specifically for heavy marine equipment. Shanghai Port provides unparalleled global connectivity with the densest network of direct mainline vessel services, ensuring efficient routing to all major maritime regions. Our logistics team coordinates pre-shipment documentation, including precise cargo manifests and ISPM 15 certificates, well in advance to maximize port turnaround time. Standard lead time from order confirmation to vessel departure is maintained at 10-14 working days, subject to final destination and vessel schedule availability.

The following table details our standard packaging configurations based on anchor specifications:

| Packaging Type | Key Features | Max Anchor Weight | ISPM 15 Compliance |

|---|---|---|---|

| Standard Wooden Crate | Kiln-dried plywood, VCI paper lining, steel strapping, dunnage | 500 kg | Fully Compliant |

| Reinforced Steel Pallet | Integrated welded steel base, extended corner posts, heavy-duty strapping | 2,500 kg | Fully Compliant |

| Custom Heavy-Duty Crate | Laminated hardwood, internal bracing, marine sealant coating | 5,000+ kg | Fully Compliant |

Pre-shipment quality control includes rigorous verification of packaging integrity, lashing point security, and documentation accuracy. This systematic approach, combined with strategic port utilization, ensures your high holding power anchor arrives at its destination in optimal condition, ready for immediate deployment, while fully satisfying international maritime shipping regulations and minimizing supply chain disruptions.

Contact Star Marine

For marine operators and procurement specialists seeking reliable, high-performance anchoring solutions, Hangzhou Star Marine Technology Co., Ltd. stands as a trusted global supplier of advanced marine equipment. Our flagship product, the high holding power anchor, is engineered to meet the rigorous demands of commercial shipping, offshore operations, and large vessel mooring applications. Designed with optimized fluke geometry, enhanced weight distribution, and superior seabed penetration characteristics, our anchor delivers unmatched holding strength across a wide range of seabed conditions—including sand, mud, and mixed terrain. Built to comply with international classification society standards such as ABS, CCS, DNV, and LR, each unit undergoes stringent quality control and material testing to ensure long-term durability and operational safety.

At Hangzhou Star Marine Technology, we understand that selecting the right anchoring system involves more than just product specifications—it requires technical collaboration, accurate load analysis, and vessel-specific customization. That’s why we offer direct access to our dedicated Product Management team, led by Kacher YE, who brings over a decade of experience in marine anchoring systems and export logistics. Whether you are specifying anchors for new vessel construction, retrofit projects, or fleet standardization, Kacher provides expert guidance on anchor selection, chain compatibility, rode configuration, and certification documentation.

We invite global partners, shipyards, and marine equipment distributors to contact us for comprehensive technical support and competitive export pricing. As an ISO 9001-certified manufacturer, we maintain strict adherence to production timelines and export regulations, ensuring on-time delivery to ports worldwide. Our export network spans Southeast Asia, the Middle East, West Africa, and the Americas, supported by full documentation services including certificates of origin, inspection reports, and shipping coordination.

To request a detailed product specification sheet, pricing quotation, or technical consultation for the high holding power anchor, please reach out directly to Kacher YE, Product Manager, via email at [email protected]. We respond to all inquiries within 12 business hours and can provide CAD drawings, load test data, and classification approvals upon request.

Below is an overview of standard high holding power anchor models currently available for export:

| Model | Weight Range (kg) | Recommended Vessel Size (LOA) | Holding Power (kN) | Material Grade | Certification Options |

|---|---|---|---|---|---|

| HHP-100 | 100 – 300 | 20 – 40 m | 85 – 160 | ASTM A494 GR. M35-1 | CCS, ABS, DNV |

| HHP-200 | 301 – 800 | 40 – 70 m | 165 – 320 | ASTM A494 GR. M35-1 | ABS, LR, CCS |

| HHP-300 | 801 – 1,500 | 70 – 100 m | 325 – 610 | ASTM A494 GR. M35-1 | DNV, LR, CCS, ABS |

| HHP-400 | 1,501 – 3,000 | 100 – 150 m | 615 – 1,150 | ASTM A494 GR. M35-1 | All major classes |

All models are available with optional galvanization, customized shank configurations, and integrated anchor handling features. Contact Kacher YE today to ensure your vessel is equipped with a truly high holding power anchoring solution backed by engineering excellence and global service support.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160