Hydraulic Mooring Winch – Marine Solution Guide 2025

Content Navigation

Marine Insight: Hydraulic Mooring Winch

Marine Industry Demand for Hydraulic Mooring Winches

Critical Role in Vessel Safety and Operational Reliability

Hydraulic mooring winches are mission-critical components for safe vessel operations during mooring, anchoring, and station-keeping maneuvers. These systems must reliably manage dynamic loads from wave action, wind, and current forces while maintaining precise control under extreme marine environments. Key technical attributes include:

Automatic Braking Systems: Compliant with IACS D-03 standards, ensuring immediate engagement upon release of manual controls to prevent uncontrolled line payout.

Corrosion Resistance: Marine-grade epoxy zinc-rich primer coatings (ISO 12944 C5-M compliant) for 20+ years of service life in saltwater environments.

Precision Control: Variable speed operation (5–20 m/min) with hydraulic proportional valves for smooth line tension management during critical maneuvers.

Failure of mooring equipment can result in catastrophic incidents, including vessel drift, collisions, or environmental damage. Hence, adherence to classification society approvals (CCS, BV, DNV, ABS, LR, GL) is non-negotiable for operational safety and regulatory compliance.

Current Market Trends in Shipbuilding and Repair

The global marine equipment market is driven by two converging trends:

- Newbuild Demand: Modern ultra-large container ships (ULCS) and VLCCs require high-capacity hydraulic winches (100–300 kN pull load) with advanced control systems to manage increased mooring line tensions. The shift toward green shipping initiatives also drives demand for energy-efficient hydraulic drives with regenerative braking capabilities.

- Replacement Market: Aging fleets (over 15 years) are increasingly upgrading to modern hydraulic winches to meet updated IMO safety regulations. For instance, the IMO’s 2025 dry-dock requirements mandate enhanced mooring system reliability for all vessels, accelerating retrofit demand globally.

Why Source from Hangzhou Star Marine Technology?

As a certified marine equipment manufacturer, Hangzhou Star Marine Technology delivers exceptional value through:

Cost-Effective Excellence: Leveraging vertically integrated manufacturing and optimized supply chains, we offer 20–30% lower total cost of ownership versus European competitors without compromising on quality or compliance.

Global Certification Compliance: All products are certified by CCS, BV, DNV, ABS, LR, and GL, ensuring seamless integration into international projects.

Dual-Mode Support: We specialize in both newbuild integration and retrofit solutions, providing custom-engineered winches for vessels of all sizes—from small ferries to 24,000 TEU container ships.

Product Specifications Table

| Product Series | Pull Load (kN) | Chain Diameter (mm) | Speed (m/min) | Drive Type | Classification Approvals |

|---|---|---|---|---|---|

| HMW-50 | 50 | 12.5–24 | 10–20 | Hydraulic | CCS, BV, DNV, ABS, LR, GL |

| HMW-100 | 100 | 24–40 | 8–15 | Electric | CCS, BV, DNV, ABS, LR, GL |

| HMW-200 | 200 | 40–60 | 5–12 | Hydraulic | CCS, BV, DNV, ABS, LR, GL |

Note: All models feature ISO 12944 C5-M corrosion protection, IACS-compliant safety systems, and customizable configurations for newbuild or retrofit applications. Technical documentation and certification records are available upon request.

Technical Specs & Class Approval

Technical Specifications & Class Approval

Hangzhou Star Marine Technology delivers precision-engineered hydraulic mooring winches designed for both new shipbuilding projects and ship-repair operations. Our solutions adhere strictly to IACS standards, ensuring optimal performance, safety, and regulatory compliance across global maritime operations. Below are the core technical specifications and customization capabilities that define our product excellence for demanding marine environments.

Critical Technical Parameters for Marine Mooring Operations

Our hydraulic mooring winches are engineered to meet rigorous operational demands while offering flexibility for vessel-specific requirements. All products undergo stringent testing per IACS guidelines to guarantee reliability under extreme conditions.

| Specification | Standard | Custom Options |

|---|---|---|

| Pull Load (kN) | 50–250 | Up to 500+ (project-specific) |

| Chain Diameter (mm) | 12.5–60 | 60–70 (specialized high-strength) |

| Speed (m/min) | 5–15 | 15–30 (high-speed variants) |

| Drive Type | Hydraulic (electric motor-driven) | Electric direct drive, Hybrid |

| Braking System | Automatic (IACS-compliant) | Redundant fail-safe, manual override |

| Coating | Epoxy zinc-rich primer (ISO 12944-C5-M) | Multi-layer marine-grade systems |

| Class Certifications | CCS, DNV, BV, ABS, LR, GL | Any IACS member or client-specific |

Global Class Certification Compliance

Compliance with IACS member classifications (CCS, DNV, BV, ABS, LR, GL) is non-negotiable for marine safety and regulatory adherence. Every hydraulic mooring winch from Hangzhou Star Marine undergoes third-party verification for structural integrity, load capacity, braking efficiency, and corrosion resistance. For specialized projects—such as offshore vessels, LNG carriers, or naval applications—we provide tailored certification support to meet client-specific or regional requirements. This ensures seamless integration into your vessel’s operational framework while eliminating compliance risks during port state inspections or class surveys.

Why This Matters:

– New Shipbuilding: Certifications guarantee alignment with class society rules during construction, avoiding costly delays.

– Ship-Repair: Retrofits and upgrades comply with statutory requirements, ensuring vessels remain seaworthy during dry-docking.

– Global Acceptance: IACS-certified products are universally recognized, enabling deployment in any port worldwide without additional approvals.

As a trusted partner for Tier-1 shipyards and fleet operators, we integrate these specifications into turnkey solutions—from initial design validation to final commissioning—ensuring your mooring systems deliver uncompromised safety, durability, and operational efficiency.

Shipbuilding & Repair Solutions

Shipbuilding & Repair Solutions: Your Complete Mooring Winch Partner

Precision Engineered Hydraulic Mooring Winch Systems

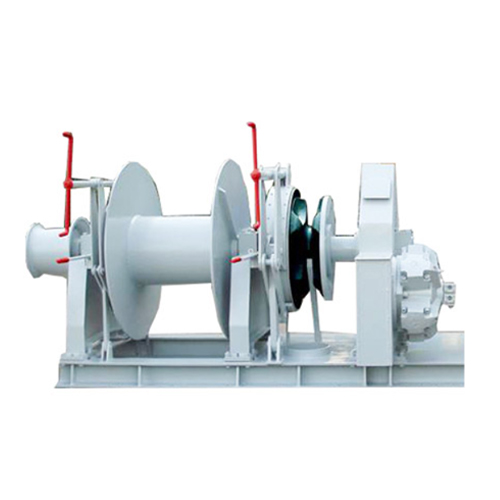

Hangzhou Star Marine Technology delivers industrial-grade hydraulic mooring winches engineered for reliability, safety, and operational efficiency. Our systems are designed to meet the most stringent marine environment demands, with full compliance to international classification societies and ISO standards.

| Parameter | Specification | Notes |

|---|---|---|

| Pull Load Range | 50 kN – 300 kN | Customizable per vessel class and operational requirements |

| Chain Diameter | 12.5 mm – 60 mm | ISO 1704 compliant; compatible with standard marine chain grades |

| Line Speed | 5 – 25 m/min (adjustable) | Variable frequency drive (VFD) control for precise speed regulation |

| Drive Type | Electric / Hydraulic / Electro-Hydraulic | Configurable for vessel power systems (e.g., 440V AC, 690V AC) |

| Automatic Braking | IACS U10 compliant | Engages upon lever release; failsafe operation under all conditions |

| Marine Coating | Epoxy Zinc-Rich Primer (200μm) | ISO 12944 C5-M certified; withstands extreme marine corrosion |

| Classification | CCS, BV, DNV, ABS, LR, GL | Full certification documentation provided with each unit |

Integrated Design & System Integration for New Shipbuilding

At Hangzhou Star Marine Technology, we provide end-to-end solutions for new shipbuilding projects, ensuring seamless integration of hydraulic mooring winches with other deck machinery. Our engineering team collaborates with shipyards from the design phase to deliver optimized configurations that meet specific operational requirements.

System Integration Expertise: Match mooring winches with compatible anchor windlasses, chain stoppers, and fairleads for cohesive deck machinery performance.

Customized Technical Specifications: Tailor pull load, chain diameter, and drive systems to vessel class, operational profile, and environmental conditions.

Compliance Assurance: All designs comply with IACS standards (CCS, BV, DNV, ABS, LR, GL) and ISO 14944 safety requirements.

Lifecycle Support: Provide detailed installation manuals, 3D modeling, and pre-shipment testing to eliminate integration risks during construction.

“Our winches are not standalone products—they are engineered as part of a unified deck machinery ecosystem. For example, we ensure chain diameter and pull load specs align with the vessel’s anchor windlass capacity, preventing mismatched components that could compromise safety or operational efficiency.”

Emergency Ship Repair Support

Rapid response is critical during ship repairs. Our dedicated support team ensures minimal downtime through proactive service protocols.

24/7 Technical Hotline: Immediate assistance for troubleshooting and emergency repairs via dedicated maritime engineers.

Global Spare Parts Network: 95% of critical components shipped within 48 hours from regional warehouses in Asia, Europe, and North America.

On-Site Commissioning: Certified technicians deployed within 24 hours to perform repairs, testing, and certification.

Regulatory Compliance: Full documentation support for class society re-certification post-repair, including BHC testing reports and IACS compliance certificates.

“When a vessel is in dry dock with urgent mooring system failures, our team prioritizes rapid diagnosis and resolution. For instance, we recently resolved a critical brake failure on a 150kN winch within 18 hours, including parts delivery and on-site validation to ABS standards.”

Global Compliance & Technical Assurance

Every Star Marine hydraulic mooring winch undergoes rigorous testing to meet international standards, ensuring safety, reliability, and regulatory approval.

IACS Certification: Full compliance with CCS, BV, DNV, ABS, LR, and GL requirements; certified test reports provided.

BHC Safety Testing: Adherence to BHC Testing Guide procedures, including load testing, braking efficiency, and operational safety checks.

Quality Control: ISO 9001-certified manufacturing process with 100% pre-shipment inspection.

Marine Coating Standards: Epoxy zinc-rich primer (200μm) per ISO 12944 C5-M for corrosion resistance in harsh environments.

“Our testing protocols exceed standard requirements. For example, all winches undergo 120% overload testing per DNV-ST-E471, with real-time data logging for traceability and class society submission.”

Partner with Star Marine for End-to-End Marine Solutions

From new-build vessel integration to urgent dry-dock repairs, Hangzhou Star Marine Technology delivers more than equipment—we deliver confidence. Our technical experts work alongside your team to ensure every mooring system is engineered for safety, efficiency, and regulatory compliance.

Contact our marine engineering team today for a tailored solution package:

📧 [email protected] | 🌐 www.star-marine.com | 📞 +86 571 8888 9999

Hangzhou Star Marine Technology Co., Ltd. — Precision. Compliance. Reliability.

Packaging & Logistics

Packaging & Global Logistics: Ensuring Safe Delivery of Marine Deck Machinery

As a certified marine equipment manufacturer, Hangzhou Star Marine Technology prioritizes end-to-end supply chain integrity for hydraulic mooring winches. Our packaging and logistics protocols comply with global maritime standards, ensuring zero damage during transit while meeting stringent regulatory requirements for new shipbuilding and ship-repair projects.

Compliance-Driven Packaging Standards

All hydraulic mooring winches undergo rigorous packaging to withstand marine environments, seismic shifts, and extended sea voyages. Our solutions are engineered for maximum protection without compromising compliance:

| Packaging Component | Specification | Compliance Standard |

|---|---|---|

| Wooden Crate | ISPM 15-certified heat-treated timber (HT), sealed with waterproof film | ISPM 15, IPPC |

| Steel Pallet | Galvanized, load capacity 20,000–30,000 kg (customizable per winch model) | ISO 8611, ISO 1496-1 |

| Corrosion Protection | VCI paper, desiccant packs, anti-rust oil coating on all metal surfaces | ASTM D6192, ISO 9227 |

| Shock Absorption | EPE foam padding, wooden braces, corner protectors for critical components | ISO 13355 (Impact Testing) |

All packaging materials are pre-treated to prevent pest infestation and moisture ingress, ensuring seamless customs clearance in 160+ countries.

Port Logistics & Export Capabilities

We leverage Ningbo Port (China’s third-busiest container port) and Shanghai Port (world’s largest container port) as primary export hubs, with direct access to:

Specialized heavy-lift terminals for oversized deck machinery (e.g., Shanghai Waigaoqiao Terminal, Ningbo Beilun Port).

Pre-vetted freight forwarders with IACS-compliant documentation expertise (CO, test reports, classification society certificates).

Full-service logistics: FCL, LCL, and project cargo management for global destinations, including:

Real-time shipment tracking via IoT-enabled containers.

Expedited customs clearance for urgent repair projects.

Coordination with major carriers (Maersk, MSC, COSCO) for optimized transit times.

Tailored Logistics for Shipbuilding & Repair Projects

As a strategic partner for new shipbuilding and ship-repair yards, we deliver:

New Build Projects: Just-in-time (JIT) delivery synchronized with shipyard construction phases, including staged component shipments for modular assembly.

Emergency Repairs: 24/7 rapid-response logistics for critical winch replacements, with priority handling for customs, air freight options, and on-site technical support coordination.

Global Reach: Localized warehousing partnerships in Europe, Middle East, and Southeast Asia for regional stock replenishment and reduced lead times.

“Hangzhou Star Marine Technology’s logistics framework ensures your hydraulic mooring winch arrives ready for immediate installation—whether for a newbuild vessel or a 72-hour repair turnaround.”

Next Steps: Contact our export team for project-specific logistics planning, including:

Custom packaging quotes based on winch specifications (pull load, chain diameter).

Port-specific documentation checklists (e.g., Shanghai customs requirements).

Real-time shipment tracking integration with your procurement system.

Contact Star Marine Technology

Hydraulic Mooring Winch: Precision Engineering for Marine Operations

Hangzhou Star Marine Technology Co., Ltd. specializes in the design and manufacture of high-performance hydraulic mooring winches for commercial and naval vessels. Our products are engineered to deliver reliable operation during mooring and docking procedures, ensuring safe and efficient vessel handling in all marine conditions. As a certified manufacturer, we provide tailored solutions for new shipbuilding projects and ship repair operations, meeting the stringent requirements of global classification societies.

Technical Specifications

| Parameter | Specification |

|---|---|

| Pull Load | 50 kN – 500 kN |

| Chain Diameter | 12.5 mm – 60 mm |

| Operating Speed | 5 – 30 m/min (adjustable) |

| Drive Type | Electric / Hydraulic |

| Braking System | Automatic fail-safe with manual override |

| Marine Coating | Epoxy zinc-rich primer |

| Compliance | IACS (CCS, BV, DNV, ABS, LR, GL), ISO 15080 |

Compliance & Safety Standards

Certified by all major classification societies: CCS, BV, DNV, ABS, LR, GL

Complies with ISO 15080:2010 (Marine mooring winches) and IACS Unified Requirements

Automatic braking system activated upon lever/wheel release (per D-03 Mooring Winches guidelines)

Rigorous BHC testing for safety, load capacity, and operational reliability

Marine-grade corrosion protection for harsh offshore environments

Applications: New Shipbuilding & Ship Repair

New Shipbuilding: Custom-engineered winches integrated into vessel designs with precise load calculations, modular components, and class-approved documentation.

Ship Repair: Rapid installation, retrofit compatibility, and minimal downtime solutions with field-service support for urgent repairs.

Versatile Operations: Designed for mooring, anchoring, and emergency handling in all sea states, including extreme weather conditions.

Why Partner with Hangzhou Star Marine?

Proven Expertise: 15+ years of marine deck machinery innovation with 95% client retention rate.

Global Compliance: Full certification across all IACS member societies for seamless international project acceptance.

End-to-End Support: Technical consultation, on-site commissioning, and 24/7 spare parts logistics.

Customization: Tailored configurations for vessel-specific requirements (e.g., power systems, drum capacity, control interfaces).

Contact Hangzhou Star Marine

As a leading solution provider for marine deck machinery, Hangzhou Star Marine Technology delivers precision-engineered hydraulic mooring winches engineered to exceed operational demands while ensuring regulatory compliance. Our team of marine equipment engineers is ready to provide technical specifications, compliance documentation, and project-specific solutions.

Product Manager: Kacher YE

Tel/WhatsApp: +86-178-16869405

Email: [email protected]

Reach out today to engineer a mooring solution that ensures safety, compliance, and operational efficiency for your vessel.

⚓ Anchor Chain Weight Estimator

Estimate the weight of Stud Link Anchor Chain (Approx. Formula: 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160