Marine Gate Valve – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Gate Valve

Marine Gate Valve Industry Demand and Strategic Sourcing Advantages

Marine gate valves represent a fundamental component in the hydraulic and piping systems critical for vessel safety and operational integrity. Their primary function within ballast water management, fire main systems, fuel transfer, seawater cooling circuits, and bilge networks directly impacts a vessel’s stability, firefighting capability, propulsion reliability, and environmental compliance. Failure of a gate valve in high-pressure or critical service applications can lead to catastrophic flooding, uncontrolled fire spread, loss of propulsion, or significant pollution incidents. International conventions, particularly SOLAS (Safety of Life at Sea) and MARPOL (Marine Pollution), mandate stringent performance and reliability standards for these valves. They must consistently provide full-bore flow with minimal pressure drop during operation and guarantee absolute shutoff integrity when closed, often under extreme conditions of pressure, temperature, and corrosive seawater exposure. The non-return functionality inherent in properly specified gate valves is equally vital for preventing backflow in systems like fire mains, ensuring pump efficiency and system readiness during emergencies. Consequently, the marine industry demands gate valves constructed from robust, corrosion-resistant materials like ASTM A216 Gr.WCB steel with precise machining tolerances, certified seat sealing, and resilient stem packing to prevent leakage throughout extended service cycles. Reliability is not optional; it is a non-negotiable requirement for safe vessel operation and regulatory adherence.

Sourcing high-performance marine gate valves from Hangzhou Star Marine Technology offers significant economic and technical advantages without compromising on safety-critical quality. Our integrated manufacturing facility in Hangzhou operates under strict ISO 9001:2015 certified quality management systems, ensuring every valve undergoes rigorous material verification, dimensional inspection, and pressure testing per international standards. We leverage China’s advanced metallurgical capabilities and efficient production scale to deliver valves meeting or exceeding ABS, DNV, LR, CCS, and other major classification society requirements at a substantially lower total cost of ownership compared to Western or regional alternatives. This cost-effectiveness stems from optimized supply chains, reduced overhead, and our engineering focus on eliminating waste while maintaining precision. Crucially, Star Marine does not achieve this value through material or process compromise; our valves utilize certified marine-grade materials and incorporate design features like renewable seats and blowout-proof stems as standard. The table below illustrates our compliance framework against key industry benchmarks.

| Standard / Requirement | Typical Industry Baseline | Star Marine Technology Compliance |

|---|---|---|

| Material Specification | ASTM A216 Gr.WCB common | ASTM A216 Gr.WCB (Melt Treated) + Full Mill Certs |

| Pressure Testing | Shell Test: 1.5x MAWP | Shell Test: 1.5x MAWP + Seat Test: 1.1x MAWP |

| Classification Society | ABS/DNV Type Approval common | ABS, DNV, LR, CCS, BV, RINA Type Approved |

| Traceability | Batch Level typical | Full Heat Number Traceability per Valve |

| Seat Sealing | Meets API 598 common | Exceeds API 598 Leakage Rates |

This combination of uncompromised safety performance, comprehensive certification, and economically advantageous pricing positions Hangzhou Star Marine Technology as the strategic sourcing partner for vessel operators and shipyards globally. We deliver valves that safeguard crew, cargo, and the marine environment while optimizing procurement budgets – a critical value proposition in today’s competitive maritime market. Partnering with Star Marine ensures access to technically superior, regulation-compliant gate valves that form the reliable backbone of essential marine systems.

Technical Specs & Approval

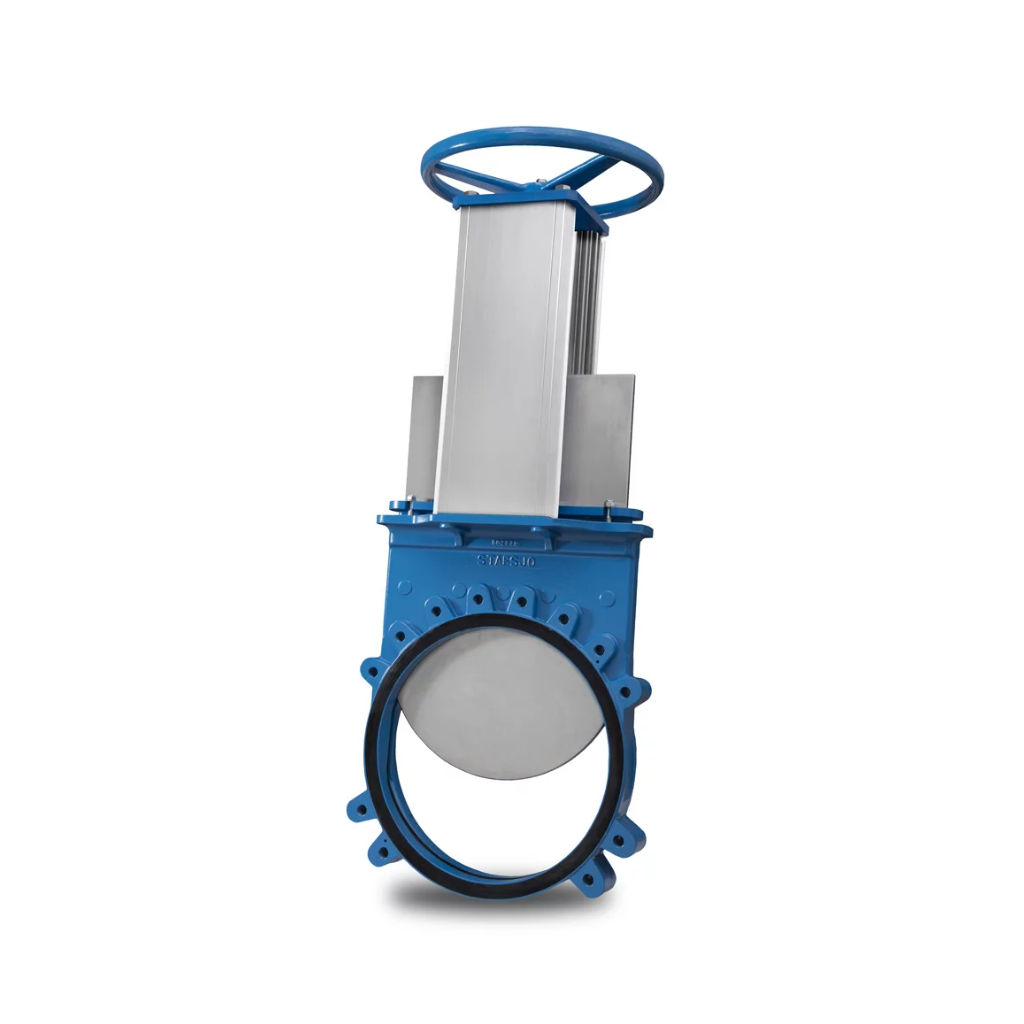

Hangzhou Star Marine Technology Co., Ltd. provides high-performance marine gate valves engineered for reliability, durability, and compliance with international maritime standards. These valves are essential components in shipboard piping systems, used primarily for isolation in seawater, freshwater, fuel oil, lubricating oil, and low-pressure steam applications. Designed for both above-deck and below-deck installations, our marine gate valves ensure tight shutoff, minimal flow resistance, and long service life in demanding marine environments.

The marine gate valves manufactured by Hangzhou Star Marine Technology are available in two primary body materials: Bronze and Cast Steel. Bronze gate valves are ideal for low to medium pressure systems involving seawater and freshwater, offering excellent corrosion resistance and machinability. Cast Steel gate valves are suited for higher pressure and temperature applications, including fuel and lube oil systems, where mechanical strength and thermal stability are critical. All internal components, including the wedge or disc, stem, and seat, are crafted from materials compatible with the body to prevent galvanic corrosion and ensure reliable sealing performance.

Valve pressure ratings range from PN6 to PN40, allowing selection based on system requirements. PN6 valves are suitable for low-pressure ventilation and drainage systems, while PN16 and PN25 variants are commonly used in general service lines such as cooling water and ballast systems. PN40 valves meet the demands of high-pressure fuel transfer and steam lines, providing robust performance under elevated operational conditions. Each valve undergoes rigorous hydrostatic and pneumatic testing to verify pressure integrity and leakage standards in accordance with classification society requirements.

Our marine gate valves are manufactured to comply with international standards, including JIS (Japanese Industrial Standards) and DIN (Deutsches Institut für Normung), ensuring global interchangeability and acceptance. JIS-compliant valves are typically used in vessels built to Japanese specifications, while DIN-compliant models are preferred in European and many modern shipbuilding projects. All valves are certified by recognized classification societies such as CCS, LR, DNV, ABS, and NK, confirming adherence to structural, material, and quality control benchmarks.

Below is a detailed summary of technical parameters for our marine gate valve product line:

| Parameter | Bronze Gate Valve | Cast Steel Gate Valve |

|---|---|---|

| Body Material | ASTM B61/B62 Bronze | ASTM A216 WCB Cast Steel |

| Disc/Wedge Material | Bronze or Stainless Steel | Stainless Steel |

| Stem Material | AISI 410 Stainless Steel | AISI 410 Stainless Steel |

| Seat Material | Bronze or NBR-lined | Stainless Steel or NBR |

| Pressure Rating | PN6 – PN16 | PN10 – PN40 |

| Temperature Range | -20°C to +200°C | -29°C to +425°C |

| End Connection | Flanged (JIS 5K/10K, DIN PN10/16/25/40) | Flanged (JIS 10K/16K/20K, DIN PN16/25/40) |

| Operation Type | Rising Stem, Handwheel Operated | Rising Stem, Handwheel or Gear Operated |

| Testing Standard | GB/T 13927, ISO 5208 | GB/T 13927, ISO 5208 |

| Certification | CCS, LR, DNV, ABS, NK | CCS, LR, DNV, ABS, NK |

These technical specifications reflect the engineering excellence and quality assurance processes implemented at Hangzhou Star Marine Technology. Our marine gate valves are designed to meet the operational demands of modern maritime vessels, ensuring safety, efficiency, and compliance across global fleets.

Shipbuilding Solutions

Marine Gate Valve Export Solutions for Shipbuilding & Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine gate valve solutions tailored for global shipyards and repair facilities. As a certified manufacturer adhering to ISO 9001:2015 and IACS standards, we specialize in providing robust, seawater-resistant gate valves critical for ballast, bilge, cooling, and firefighting systems. Our integrated approach ensures seamless integration into new vessel construction while offering rapid-response support for urgent repair and retrofit projects, minimizing vessel downtime.

Understanding the time-sensitive nature of maritime operations, Star Marine maintains dedicated export coordination teams and strategic inventory hubs across Asia, Europe, and the Americas. This enables expedited order processing, with standard lead times of 15-25 days for common configurations and emergency response within 72 hours for critical repair scenarios. All valves undergo rigorous pressure testing per API 598 and material verification to guarantee compliance with ABS, DNV, LR, and CCS requirements, eliminating rework risks during installation.

Technical specifications for our core marine gate valve series are detailed below, reflecting our commitment to durability in harsh marine environments:

| Parameter | Specification Range | Standard Compliance |

|---|---|---|

| Size Range | DN50 to DN600 (2″ to 24″) | ISO 5208, API 600 |

| Pressure Rating | PN16 to PN40 / Class 150 to Class 300 | ISO 7005, ASME B16.5 |

| Body Materials | ASTM A216 WCB, Ductile Iron, CF8M SS | ASTM A126, A395, A351 |

| Seat Seal Options | PTFE, RPTFE, Metal-to-Metal | API 6D |

| Certifications | DNV-GL, ABS, LR, CCS, KR, RINA | IACS Unified Requirements |

For newbuild projects, we collaborate directly with naval architects during the design phase, providing 3D modeling support and material certification packages to streamline approval workflows. Our valves feature reinforced stems and non-rising handwheels optimized for confined engine room spaces, reducing maintenance frequency. In repair contexts, our global spare parts network ensures exact-match replacements for legacy and modern valve types, backed by on-site technical assistance if required.

Star Marine’s export infrastructure includes consolidated container shipments, customs documentation expertise, and real-time logistics tracking, ensuring valves arrive shipyard-ready with all classification society documentation. We prioritize proactive communication, assigning a single export manager per project to coordinate engineering queries, production updates, and delivery scheduling. This end-to-end accountability, combined with our technical mastery of marine valve systems, establishes Hangzhou Star Marine Technology as a trusted partner for mission-critical valve supply across the international maritime sector. Partner with us to secure valves that meet the sea’s demands without delaying your build or repair schedule.

Packaging & Logistics

Proper packaging and logistics are critical components in the successful export of marine gate valves, ensuring that products arrive at their destination in optimal condition while complying with international regulations. At Hangzhou Star Marine Technology Co., Ltd., we prioritize robust packaging solutions designed to withstand the rigors of global shipping, particularly for heavy-duty marine equipment such as gate valves. Our standard packaging methods include the use of ISPM 15 certified wooden cases and reinforced steel pallets, both of which are engineered to protect the integrity of the valves during transit.

All wooden packaging materials used in our export shipments comply with the International Standards for Phytosanitary Measures No. 15 (ISPM 15). This globally recognized regulation mandates that wood packaging material must be heat-treated and officially marked to prevent the spread of pests and diseases across borders. Our wooden cases are constructed from high-quality, kiln-dried timber, treated and stamped accordingly, ensuring full compliance with phytosanitary requirements in all major export markets, including the United States, European Union, Australia, and Southeast Asia. These cases provide excellent shock absorption and environmental protection, safeguarding valves against moisture, corrosion, and mechanical impact.

For added structural support, especially for larger or high-weight gate valves, we utilize steel pallets. These pallets offer superior durability and load-bearing capacity, making them ideal for containerized ocean freight. Steel pallets are resistant to deformation, moisture, and pests, further enhancing the security of the cargo throughout the supply chain. Each valve is securely fastened to the pallet using industrial-grade straps or bolts, minimizing movement during handling and transportation.

Our export operations are primarily coordinated through the major Chinese port hubs of Ningbo and Shanghai, both of which rank among the busiest and most efficient container ports in the world. These strategic locations provide seamless connectivity to global shipping routes, reducing transit times and increasing logistical reliability. Prior to shipment, all packages undergo rigorous quality checks, including weight verification, labeling accuracy, and secure sealing. Customized labeling, including handling instructions, product identification, and destination details, is applied to ensure smooth customs clearance and proper handling at destination ports.

We work closely with certified freight forwarders and logistics partners to ensure compliance with all international shipping standards, including IMDG regulations for hazardous goods (if applicable) and carrier-specific requirements. Our end-to-end logistics management guarantees traceability, timely updates, and full documentation support, from packing list preparation to bill of lading issuance.

The following table outlines the standard packaging specifications for our marine gate valves:

| Packaging Type | Material Specification | Compliance Standard | Typical Use Case | Export Port |

|---|---|---|---|---|

| Wooden Case | Kiln-dried timber, nailed frame | ISPM 15 | Valves up to 50 kg, multiple units | Ningbo / Shanghai |

| Steel Pallet | Powder-coated carbon steel | ISO 8611 | Heavy valves, bulk industrial orders | Ningbo / Shanghai |

| Combined Packaging | Valve boxed, then mounted on steel pallet | ISPM 15 + ISO 8611 | High-value or sensitive shipments | Ningbo / Shanghai |

Through standardized, compliant, and resilient packaging practices, Hangzhou Star Marine Technology ensures that every marine gate valve reaches its international destination safely, efficiently, and in full regulatory compliance.

Contact Star Marine

Contact Star Marine for Precision Marine Gate Valve Solutions

Selecting the correct marine gate valve is not merely a procurement decision; it is a fundamental commitment to the operational safety, regulatory compliance, and longevity of critical vessel systems. Gate valves govern the flow of seawater, ballast, fuel, and other essential media where failure can lead to catastrophic flooding, environmental incidents, or significant operational downtime. Hangzhou Star Marine Technology Co., Ltd. stands as your dedicated engineering and export partner, specializing in the design, manufacture, and global supply of marine gate valves engineered to exceed the stringent demands of modern maritime applications. Our valves are not off-the-shelf components but meticulously crafted solutions validated against the highest international maritime classification society standards and operational requirements.

Our engineering team, led by Product Manager Kacher YE, possesses deep expertise in marine fluid dynamics, material science under corrosive seawater conditions, and the complex regulatory landscape governing international shipping. We understand that specifications on paper must translate into reliable, maintenance-efficient performance in the harsh marine environment. This expertise ensures every gate valve we export delivers mission-critical integrity throughout its service life, minimizing lifecycle costs and safeguarding operational continuity. We maintain rigorous quality control processes from raw material sourcing through final testing, adhering strictly to ISO 9001:2015 and specific classification society production quality plans.

The technical requirements for marine gate valves are precise and non-negotiable. The following table outlines the core specifications consistently met by Hangzhou Star Marine Technology gate valves for global export:

| Parameter | Standard Specification | Key Compliance Notes |

|---|---|---|

| Pressure Rating | PN16 / Class 150 / Class 300 | ASME B16.34, EN 1092-1 |

| Temperature Range | -20°C to +200°C (Standard) | Extended ranges available per application |

| Body/Bonnet Mat. | ASTM A216 WCB, CF8M (316SS) | DNVGL-ST-F101, EN 10213-3 compliant |

| Disc/Stem Mat. | Stainless Steel (e.g., 17-4PH, F316) | Enhanced corrosion resistance for seawater |

| Seat Seal | Reinforced PTFE / Metal-to-Metal options | Zero leakage per API 598 testing |

| Face to Face | ASME B16.10 / EN 558 Series 1 | Ensures direct replacement capability |

| Certifications | DNV-GL, ABS, LR, BV, CCS, RINA, KR, IRS | Full Type Approval and Product Certificates |

| Testing Standard | API 598, ISO 5208 Cat. A | 100% Shell & Seat tested prior to shipment |

Initiating a dialogue with our Product Management team is the essential first step towards securing valves that integrate seamlessly into your vessel’s design and meet all flag state and class requirements. Kacher YE serves as your single point of technical and commercial accountability throughout the export process. Provide your specific project parameters, including system media, design pressure/temperature, required certifications, and dimensional constraints. Kacher will conduct a thorough technical review, confirm optimal valve configuration, outline production timelines aligned with your shipyard schedule, and detail our comprehensive export documentation package – ensuring smooth customs clearance and delivery to any global port.

Do not risk system integrity or project timelines with generic valve suppliers lacking specialized marine validation. Contact Product Manager Kacher YE directly today at [email protected]. Include your project name, vessel type, required valve specifications (size, class, material), and target delivery window. Expect a detailed technical and commercial proposal within 24 business hours, reflecting Hangzhou Star Marine Technology’s commitment to precision engineering and responsive global export support for the maritime industry. Your vessel’s safety and operational efficiency demand valves engineered without compromise – partner with the experts who deliver them.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160