Marine Searchlight – Marine Solution Guide 2025

Content Navigation

Marine Insight: Marine Searchlight

Marine Searchlight: Critical Safety Equipment and Strategic Sourcing Advantage

Marine searchlights represent a non-negotiable component of vessel safety systems, mandated under international conventions like SOLAS for specific vessel types and operational profiles. Their primary function extends far beyond basic illumination; they are essential tools for collision avoidance during night operations or periods of restricted visibility, enabling bridge crews to identify navigational hazards, other vessels, and small craft at critical distances. Furthermore, searchlights are indispensable during search and rescue (SAR) operations, providing the intense, focused beam necessary to locate persons in the water or distressed vessels over significant ranges. The operational reliability of these units under harsh marine conditions – including salt spray, extreme temperatures, vibration, and constant motion – is paramount. Failure can lead directly to compromised situational awareness and heightened risk of maritime incidents. Consequently, maritime authorities and prudent shipowners demand searchlights meeting stringent performance criteria for beam intensity, range, durability, and compliance with recognized standards such as IEC 60092-507 and relevant classification society rules.

Technical specifications define effective marine searchlights. Adequate luminous intensity (measured in candela) ensures the beam penetrates fog, rain, and darkness to a sufficient operational range. Robust construction using marine-grade aluminum alloys or stainless steel is mandatory to resist corrosion. High ingress protection ratings (IP66/IP67 minimum) are critical for withstanding heavy seas and washdowns. Long operational lifespan under continuous duty cycles and compatibility with vessel electrical systems (typically 24V DC) are non-negotiable requirements. The table below outlines key parameters distinguishing compliant, high-performance units:

| Parameter | Industry Standard Requirement | Star Marine Specification Advantage |

|---|---|---|

| Minimum Beam Intensity | 100,000 cd | 150,000 – 300,000 cd |

| Effective Range (Clear) | 1.5 Nautical Miles | 2.0 – 3.5 Nautical Miles |

| Ingress Protection (IP) | IP66 | IP67 (Submersible to 1m) |

| Housing Material | Marine Aluminum | Forged Marine Aluminum Alloy |

| Operating Voltage Range | 20-32V DC | 18-36V DC (Enhanced Stability) |

| Certifications | SOLAS Ch.V Reg.34, IEC 60092 | DNV-GL, LR, ABS, CCS, RINA, CE |

Sourcing high-performance marine searchlights from Hangzhou Star Marine Technology offers significant cost-effectiveness without compromising on safety or quality. Our vertically integrated manufacturing within China leverages optimized supply chains and controlled production processes, eliminating unnecessary markups inherent in multi-tiered global distribution. Crucially, this cost advantage is achieved while maintaining rigorous adherence to international quality management systems (ISO 9001:2015) and direct oversight of every production stage. Star Marine subjects all searchlight components to accelerated salt spray testing, thermal cycling, and vibration analysis exceeding standard requirements, ensuring longevity and reducing the total cost of ownership through minimized maintenance and replacement frequency. We provide comprehensive technical support, including custom beam pattern configurations and seamless integration assistance, alongside responsive global after-sales service. This combination of certified performance, proven durability under real-world conditions, and a transparent, value-driven pricing structure makes Star Marine the strategic partner for vessel operators prioritizing both uncompromised safety and operational efficiency in marine searchlight procurement. Investing in our equipment directly translates to enhanced navigational safety and reduced lifecycle costs.

Technical Specs & Approval

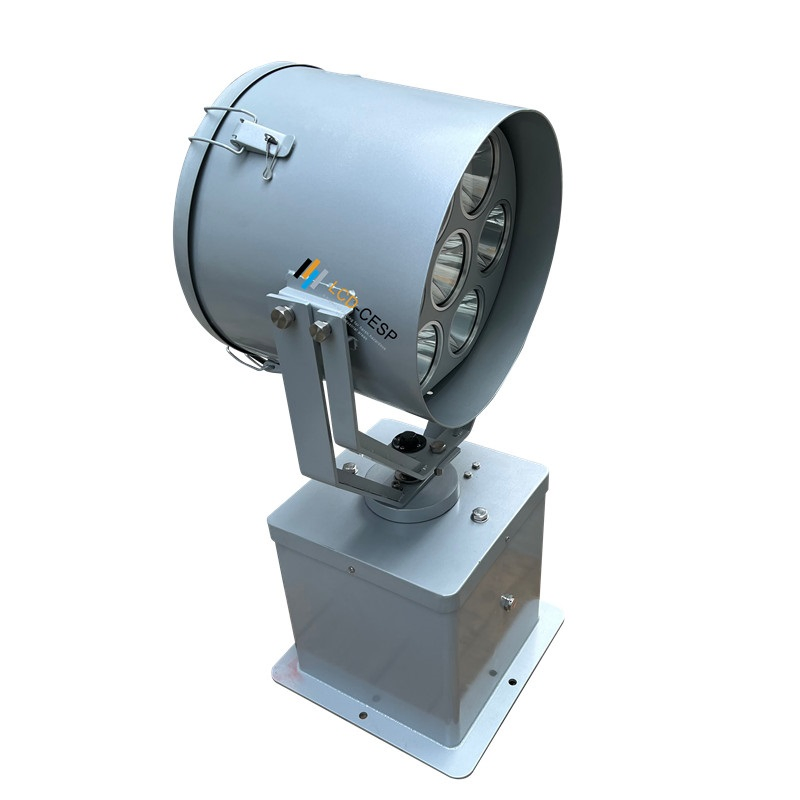

The marine searchlight is a critical component in vessel navigation, safety, and operational efficiency, especially during low-visibility conditions or nighttime operations. Hangzhou Star Marine Technology Co., Ltd. manufactures high-performance marine searchlights designed for durability, reliability, and compliance with international maritime standards. These units are engineered for installation on commercial ships, offshore platforms, yachts, and naval vessels, offering superior beam intensity, long operational life, and resistance to harsh marine environments.

Constructed using high-grade aluminum alloy and marine-grade stainless steel, our searchlights are optimized for corrosion resistance and structural integrity. The housing is precision-cast aluminum with a powder-coated finish for enhanced UV and salt spray resistance, while critical fasteners and mounting hardware are fabricated from AISI 316 stainless steel to prevent galvanic corrosion. This combination of materials ensures long-term performance in both tropical and arctic maritime zones.

Watertightness is a core design criterion. All searchlight models meet or exceed IP66 and IP56 ingress protection ratings, as verified through rigorous testing under IEC 60529 standards. The optical assembly is sealed with high-compression silicone gaskets and features a tempered borosilicate glass lens capable of withstanding thermal shock and mechanical impact. Internal components are conformal-coated to resist moisture accumulation and salt contamination, further enhancing reliability in high-humidity environments.

The searchlight’s optical system utilizes a precision parabolic aluminized reflector paired with a high-intensity discharge (HID) or LED lamp module, depending on model configuration. Beam angles range from 6° to 12°, enabling focused long-range illumination up to 500 meters. Lamps are easily replaceable through a rear-access hatch, and the unit supports remote or manual control via optional joystick or switch panel integration.

Mounting is facilitated through a robust stainless steel yoke assembly allowing azimuth and elevation adjustment. The design supports both fixed and rotatable installation modes, with optional 360° continuous rotation for panoramic surveillance. Vibration damping mounts are included to minimize stress from engine or wave-induced hull movement.

Below are the standard technical specifications for the Hangzhou Star Marine Technology marine searchlight series:

| Parameter | Specification |

|---|---|

| Housing Material | Die-cast aluminum alloy, powder-coated; AISI 316 stainless steel hardware |

| Lens Material | Tempered borosilicate glass with anti-reflective coating |

| Ingress Protection | IP66 (dust-tight and protected against powerful water jets) |

| Operating Temperature | -30°C to +70°C |

| Humidity Resistance | Up to 95% non-condensing |

| Light Source | LED or HID (options vary by model) |

| Beam Angle | 6° – 12° |

| Luminous Intensity | 180,000 – 350,000 candela (depending on model) |

| Power Supply | 24 VDC, 220 VAC (transformer available for AC models) |

| Power Consumption | 150 W (LED), 250 W (HID) |

| Mounting Type | Yoke mount with manual or motorized elevation and azimuth adjustment |

| Rotational Capability | Optional 360° continuous rotation with slip-ring assembly |

| Dimensions (approx.) | 320 mm (L) × 280 mm (W) × 350 mm (H) |

| Net Weight | 8.5 kg – 10.2 kg (depending on configuration) |

| Compliance Standards | IEC 60092-350, IEC 60529, IMO A.695(17), SOLAS Chapter V |

All units undergo factory performance testing, including photometric analysis, thermal cycling, and salt spray exposure per ASTM B117. Documentation and type approval support are available upon request.

Shipbuilding Solutions

Comprehensive Marine Searchlight Solutions for Shipbuilding and Repair

Hangzhou Star Marine Technology Co., Ltd. delivers engineered marine searchlight systems that meet stringent global maritime safety and operational requirements. As a specialized provider within Marine Outfittings, we integrate SOLAS-compliant lighting solutions seamlessly into new vessel construction and emergency repair workflows. Our technical expertise ensures optimal performance across diverse vessel types, from offshore support vessels to commercial tankers, while adhering to IEC 60092 and ISO 15083 standards. This commitment to regulatory alignment minimizes client risk during classification society inspections and sea trials.

For new build projects, Star Marine collaborates directly with shipyards during the design phase to optimize searchlight placement, power integration, and control system compatibility. Our engineering team provides 3D mounting schematics and load calculations, reducing installation time by up to 30% compared to standard procurement processes. This proactive approach prevents costly retrofitting and aligns with critical path scheduling in modern shipbuilding. All units undergo factory acceptance testing per IACS UR M70 protocols, with full documentation packages delivered prior to shipment.

In ship repair scenarios, our global logistics network enables 72-hour critical spare parts dispatch to major ports worldwide. We maintain strategic inventory hubs in Singapore, Rotterdam, and Houston, ensuring rapid replacement of components such as xenon lamps, sealed optical assemblies, or corrosion-resistant housings. Our 24/7 technical support team provides remote diagnostics via encrypted maritime communication channels, guiding onboard crews through troubleshooting procedures to minimize vessel downtime. This operational continuity is vital for time-sensitive repair cycles in dry dock facilities.

Key technical specifications for our flagship searchlight series demonstrate this reliability:

| Model | Beam Angle | Max Range (nm) | Certification | Housing Material | Input Voltage |

|---|---|---|---|---|---|

| ST-MLX2000 | 1.2° | 12 | DNV-GL, ABS, LR | Marine-grade SS316 | 24V DC |

| ST-MLX3500 | 0.8° | 18 | BV, RINA, CCS | Forged Aluminum | 110-240V AC |

| ST-MLX5000 | 0.5° | 24 | NK, KR, IRS | Duplex Stainless | 24V DC |

All units feature IP67-rated seals, shock resistance to 20G, and anti-fogging optical coatings validated in salt spray testing per ASTM B117. Star Marine further supports clients through lifecycle management programs, including predictive maintenance scheduling and firmware updates for smart control systems. Our export documentation complies with INCOTERMS® 2020 and includes detailed packing lists for customs clearance efficiency. By combining technical precision with responsive global service, Hangzhou Star Marine Technology ensures your vessel’s visibility systems remain mission-ready throughout its operational life. Partner with us for solutions where safety, speed, and seaworthiness converge.

Packaging & Logistics

Packaging & Logistics for Marine Searchlight Exports

At Hangzhou Star Marine Technology Co., Ltd., we ensure that all marine searchlight units are packaged to meet international shipping standards and to withstand the rigors of global transportation. As part of our commitment to product integrity and customer satisfaction, our packaging protocols are designed to protect sensitive maritime equipment from moisture, shock, vibration, and handling damage during transit. Our standard export packaging for marine searchlights includes the use of ISPM 15 compliant wooden cases and reinforced steel pallets, depending on the model, weight, and destination requirements.

Wooden cases used for export are constructed from high-grade, kiln-dried plywood or solid wood and are treated in accordance with International Standards for Phytosanitary Measures No. 15 (ISPM 15). This internationally recognized regulation ensures that all wooden packaging materials are heat-treated to eliminate pests and pathogens, thereby preventing the spread of invasive species across borders. Each wooden case is clearly marked with the official ISPM 15 stamp, including the country code, producer code, and treatment indicator (HT for heat treatment), ensuring full compliance with customs and agricultural regulations in destination countries.

For heavier or bulk shipments, marine searchlights are secured on steel pallets designed for durability and compatibility with containerized shipping. These pallets provide superior load-bearing capacity and are especially suited for long-distance ocean freight. All steel pallets are treated with anti-corrosion coatings to resist saltwater exposure during maritime transport and are welded for structural integrity. Equipment is firmly fastened using industrial-grade straps or brackets to prevent movement during loading, unloading, and sea transit.

Our export logistics are managed through the major international ports of Ningbo and Shanghai, two of the busiest and most efficient container ports in the world. These strategic locations provide seamless access to global shipping lanes, ensuring timely delivery to customers across Europe, the Americas, Africa, and Southeast Asia. All shipments are coordinated with certified freight forwarders and include full documentation, including packing lists, commercial invoices, certificates of origin, and, where required, marine insurance and export licenses.

The following table outlines the standard packaging specifications for our marine searchlight series:

| Item | Packaging Type | Dimensions (L×W×H) | Weight (kg) | Compliance Standard |

|---|---|---|---|---|

| Standard Marine Searchlight (24V) | Wooden Case | 80×60×50 cm | 28 | ISPM 15 |

| High-Intensity Searchlight (110V) | Wooden Case | 100×70×60 cm | 45 | ISPM 15 |

| Rotating Beacon Searchlight | Steel Pallet | 120×80×75 cm | 68 | ISO 1496/3 |

| Compact LED Searchlight (12V) | Wooden Case | 60×50×40 cm | 18 | ISPM 15 |

All packaging is subject to internal quality inspection prior to dispatch, ensuring that every unit arrives at its destination in optimal condition. We also accommodate special packaging requests based on customer specifications or regional import regulations.

Contact Star Marine

Contact Star Marine for Precision Marine Searchlight Solutions

Selecting the optimal marine searchlight requires navigating complex technical specifications, regulatory compliance, and global logistics. Hangzhou Star Marine Technology Co., Ltd. stands as your dedicated partner for high-intensity, seaworthy searchlight systems engineered to exceed IMO, SOLAS, and IEC 60092 standards. Our marine searchlights integrate IP68-rated sealed optics, corrosion-resistant stainless steel housings, and advanced thermal management for continuous operation in extreme maritime environments. Whether outfitting commercial vessels, offshore platforms, or naval assets, our engineering team ensures each unit delivers 360-degree azimuth rotation, precise beam control, and seamless integration with vessel power and control networks.

Global export compliance remains a critical challenge in marine equipment procurement. Star Marine mitigates this through our in-house export management division, which handles HS code classification (8539.50.00), CE/UKCA marking, customs documentation, and destination-specific certifications including ABS, DNV, and LR Type Approvals. We provide comprehensive technical dossiers, including 3D mounting drawings, vibration test reports, and EMC compliance certificates, to accelerate port clearance. Our logistics network partners with Maersk, COSCO, and Kuehne+Nagel to guarantee FCL/LCL shipments with real-time container tracking and INCOTERMS 2020 flexibility.

For project-specific technical validation or export coordination, direct engagement with our Product Management team delivers decisive advantages. Kacher YE, Product Manager for Marine Searchlight Systems, possesses 12 years of field experience optimizing searchlight performance across Arctic supply vessels, FPSOs, and high-speed craft. He leads technical consultations covering beam intensity calibration (up to 1,200,000 candela), power consumption analysis, and retrofit compatibility assessments.

Contact Details for Technical & Export Support

| Field | Information |

|---|---|

| Name | Kacher YE |

| Position | Product Manager, Marine Searchlight Systems |

| Direct Email | [email protected] |

| WeChat ID | StarMarine_Kacher |

| Typical Response | Within 4 business hours |

Initiate your project with a technical pre-qualification review. Email Kacher YE with your vessel specifications, operational requirements, and target delivery timeline. Include details such as mounting location (masthead, bridge wing, or deck crane), required beam spread (5°–60°), voltage compatibility (12/24/110/220V DC/AC), and environmental conditions (e.g., ice-class zones, tropical humidity). Our team will provide a customized compliance roadmap, 3D installation mockups, and a definitive export timeline within 72 hours.

Do not compromise on critical visibility systems. Contact Kacher YE today to receive engineered searchlight solutions backed by Hangzhou Star Marine Technology’s ISO 9001:2015-certified quality management system and 24-month global warranty coverage. Let us ensure your navigation safety systems perform flawlessly from the South China Sea to the North Atlantic. Immediate technical support awaits your inquiry.

⚓ Anchor Chain Weight Estimator

Estimate Stud Link Anchor Chain weight (Approx. 0.0219d²).

Contents of Table

Contact [email protected] Whatsapp 86 15951276160